The Importance of Point Of Production Measurement in Times of Economic Uncertainty

The global economy appears to be on the brink of widespread recession. With nations around the world closing their borders and shutting down all but the most essential of services, the outlook for at least the next six months is certainly grim.

At home, the Australian dollar has been volatile as has the Australian Stock Exchange. The outbreak of the coronavirus in China in January, combined with the normal cyclical downturn associated with Chinese New Year, has seriously impacted Australia’s exports. Add to that flow on impacts to sea freight and these are the most challenging conditions experienced by the Australian economy generally, and the mining sector specifically, for a very long time.

Australian iron ore, gas and lamb exports to be hit hard as coronavirus crisis continues https://t.co/j6g3oXjQuA

— Guardian Australia (@GuardianAus) February 12, 2020

There are some positive developments, particularly the recovery of Chinese manufacturing and general economic activity which, while slow, is occurring much more quickly than anticipated.

Mining, along with other commodity-exporting industries, is particularly exposed to this global economic and trade volatility – the vast majority of minerals produced in Australia are exported, predominantly to China.

Economic uncertainty brings with it the need for ever greater production certainty, whether it be in relation to human resources, markets, or other significant production input costs such as fuel and energy.

A critical piece of the puzzle in creating greater production certainty is ensuring that mining enterprises have in place the most innovative and effective weighing systems that can operate seamlessly throughout the supply chain, from the point of extraction to the point of sale, whether that’s delivered at wharf, FOB or CFR.

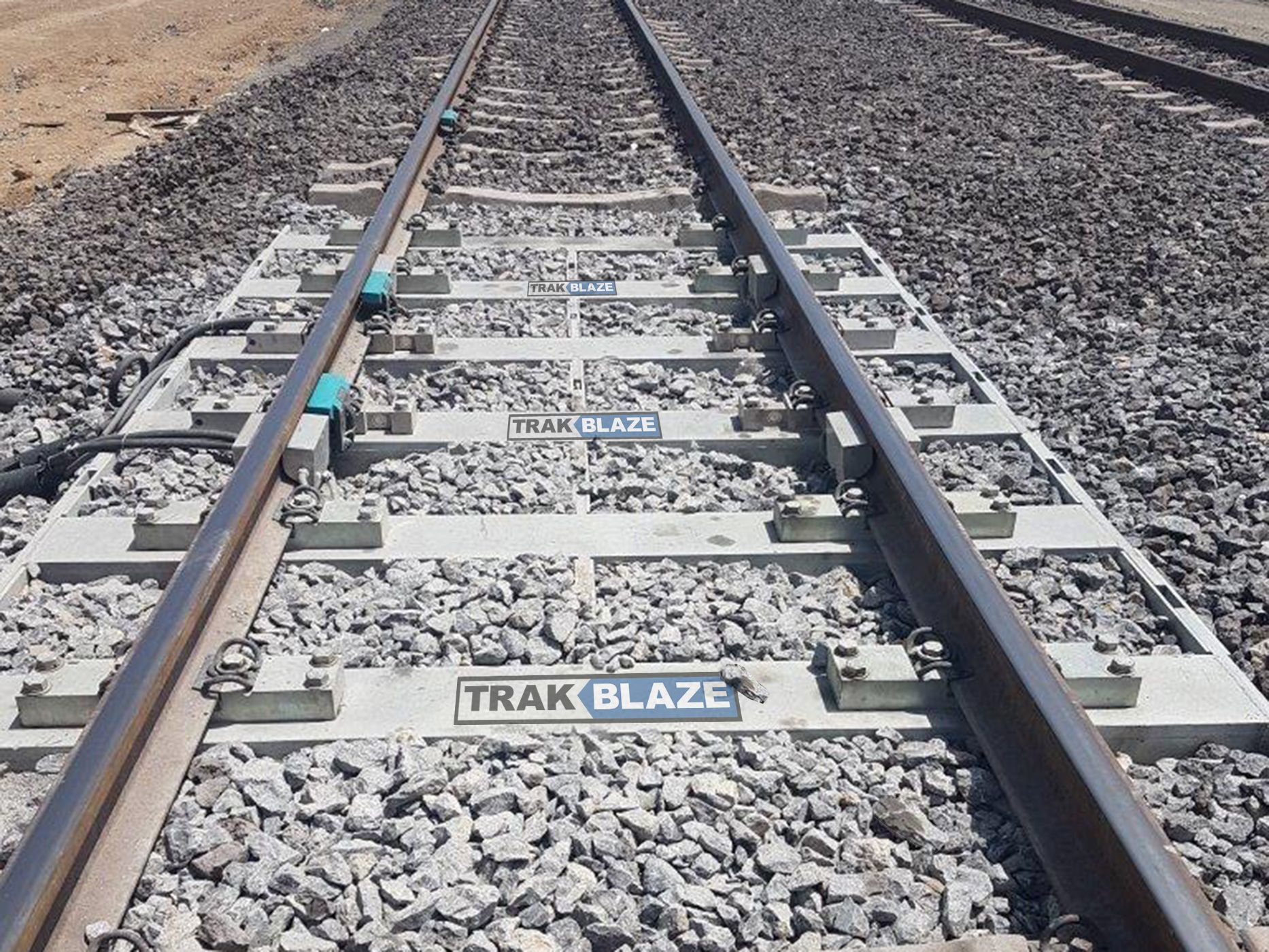

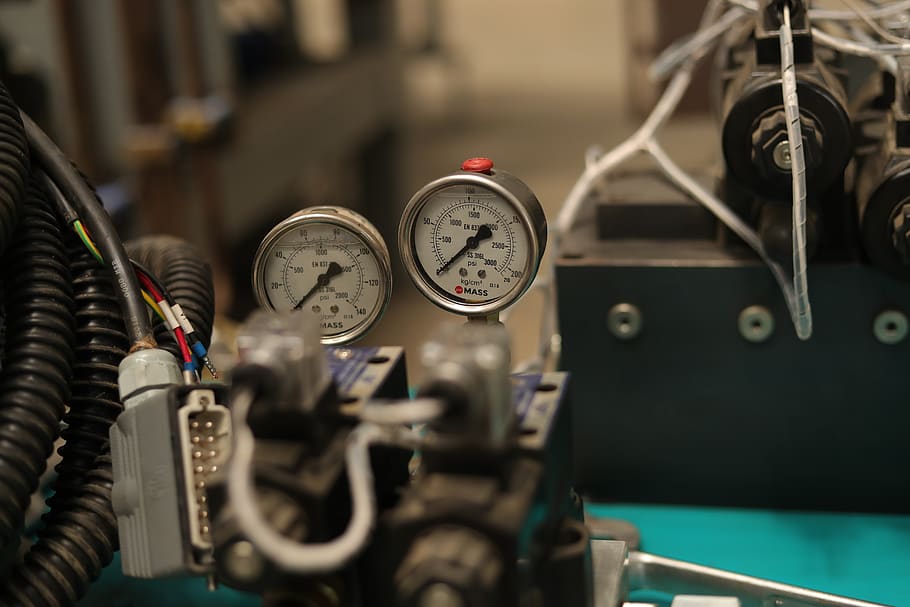

While basic weighing and measuring technology has not changed much, the ways in which it is applied and the rapidly evolving information technology interfaces mean that mining businesses have access to increasingly sophisticated enterprise solutions that enable them to capture, monitor, record, communicate and analyse volume and weight information, whether its on-site extraction and transport, transport from mine to the wharf or before and after sea-freight transport.

The increasing sophistication of volumetric scanners, more sophisticated application of in-motion weighing truck and rail weighing systems which can take measurements down to the individual axle or bogey and information technology solutions that provide immediate access to information throughout the supply chain, while minimising human interaction and the potential for error, all offer users increasing supply chain control and security that comes with clear, mistake-free data and information.

Armed with this high-quality information, miners are in a position to drive innovation, find greater efficiencies to reduce production and supply chain costs and minimise expensive wear and tear on plant and equipment. Further, this information is critical to improving safety and environmental outcomes and meeting compliance requirements.

At the end of the day, none of us is in a position to meaningfully impact the course of global economic events – all we can do is make decisions to minimise the impacts on our own business enterprises. Investing in an innovative and effective enterprise weighing and measuring system is one of the most important decisions you can make to help your business weather the winds of economic and trade volatility.