The Australian Mining Industry Underpinned Economic Growth Throughout The Pandemic. How Can Mining Sites Continue To Improve Their Operations?

The Australian mining industry is a major industry for the nation’s economic growth. A combination of mining equipment, technology and services (METS) contributed to 62% percent of all the Australian exports in 2020 and created more revenue than all sectors combined. The growth which continued in 2021, despite setbacks from COVID-19 restrictions, reflects the true growth potential of the industry and its agility in adopting innovative approaches to sustain and grow.

Owing to its contribution to the GDP of the nation, among other factors, the sector was marked as an ‘essential industry’ by the Australian government and provisioned for keeping the industry in operation by introducing enhanced health screening and sanitisation measures. The most important factor in the industry’s growth was its reliance and adoption of world-leading technological advances including cloud computing.

Mining has helped Australia weather the COVID-19 storm: Federal Minister for Resources and Water Keith Pitt explores the strength of Australia’s mining and resources sector despite COVID-19. Australian Mining. https://t.co/brI7w5tdTV pic.twitter.com/fgf0eWHvPE

— Australian Mining (@ozmining) September 24, 2021

As the country gradually prepares to change its ‘closed-border’ strategy and prepares to tackle the pandemic head on, there are challenges for everyone ahead, including the mining industry. The industry has been successful in coming out as a winner in its fight with the COVID-19 restrictions. The challenge ahead for it to overcome is boosting its profit margin. One of the areas that the mining industry in Australia should focus on is increasing productivity, cost efficiency and maximising operational profits.

Underloading, carry back and off-centre loading are some of the most pervasive issues across the mining industry This relies on legacy measurement methods and technologies. Based on our experience in optimising the load carry of our clients, these factors have huge potential to improve profitability on the operational side of the business.

Sub-optimal loading is one of the most pressing issues with mining companies that rely on traditional weighing methods. Based on our customer’s experience, around 5 to 15% of the trucks are underloaded and this directly decreases profit.

Carry back is another issue rampant across the mining industry. Load weighing scales including portable truck scales fall short of factoring in any carry back from a shift without paperwork. With a lack of enhanced weighing systems, it is hard for mine operators to get the true tally of the real load tallies.

Similarly, off-centre loading whereby trucks are not loaded optimally and result in uneven load distribution affects the performance of the truck including adding stress on some of the components, which can affect the performance and durability of truck components like tyres, axles, among others. This in turn leads to an increase in maintenance and operation costs.

Modern three-dimensional volume scanner technology has been productive in addressing these pressing issues. Along with providing accurate load and distribution scans, volumetric scanners also seamlessly integrate mining operation data with cloud hosted data centres. Because of their ability to improve operational efficiency, their adoption across the industry in Australia and outside the world has increased through the pandemic.

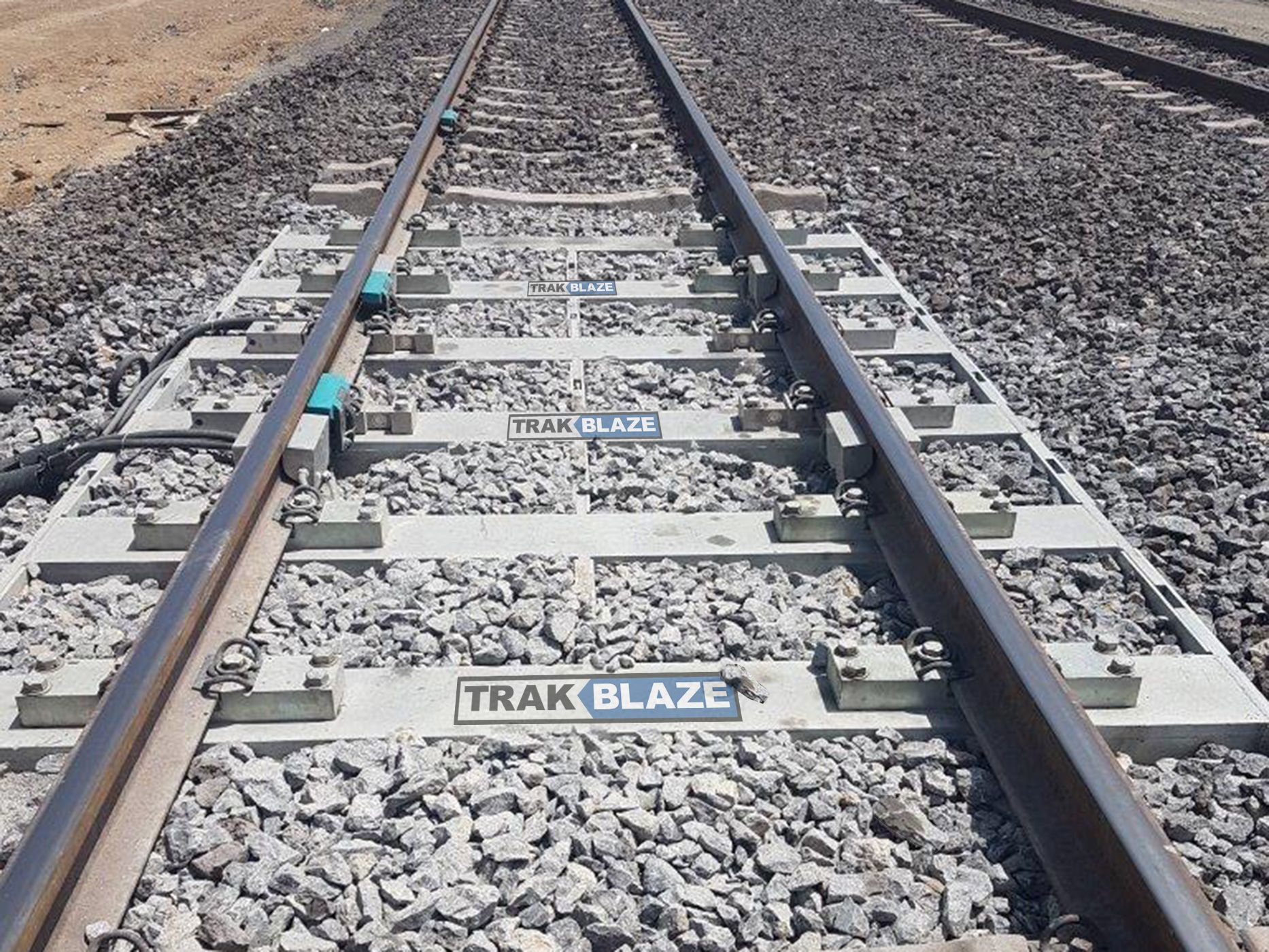

Trakblaze also offers a range of mining weighbridge scales, so that mining sites can have the option of volumetric scanner and truck weigh scales. The FORCE™ portable mining weighbridge scale has been specifically designed to endure the world’s most challenging mining environments. Unlike standard mining truck weighbridges, its modular design enables it to be configured to consider any sort of mining truck, no matter the make or model. You won’t find a better mining truck scale anywhere else on the market.

How BHP developed its most technically advanced mine: BHP has officially opened its $4.6 billion South Flank iron ore mine in the Pilbara region of Western Australia, delivering the record project both on time and on budget. Australian Mining. https://t.co/1HRAknn2yf

— Australian Mining (@ozmining) October 8, 2021

Mining operations are complex, and their transportation is equally complex involving multiple sites and multiple modes of transportation. Considering these varied scenarios, it is important that mine operators have access to seamlessly integrated mining weighbridge scales, truck volumetric scanners, rail volumetric scanners and mobile volumetric scanners – that can scan a truck or a train on the fly and store data on the cloud.

Traditional transport and vehicle scales are limited in their abilities. It is important to integrate mining scales that have advanced functionalities including better integration with load volume scanners and the ability to transmit data over the cloud in real-time. It is also equally important to consider measurement methods with cloud-backed advanced measurement tools as that assists the management and operation team to understand and tally load data.

Australia has remained at the forefront of developing cutting edge load and volumetric measurement technology for the mining industry. And as one of the leading companies, Trakblaze has the right resources and technology to improve the profit margin of mining operators across the world. Get in touch today to discuss with one of our experts.