How Weighbridge Automation Coupled With Technological Advances Is Revolutionizing the Supply Chain

Leveraging and optimizing the supply chain is integral to the success of many businesses. Proper supply chain management helps companies to eliminate excess costs and deliver products to the consumer faster. And it can be done by keeping tighter control of internal inventories, production, distribution, and sales.

Over the years, automated weighbridges have contributed significantly to improved supply chain management. Technological innovations and equipment such as sensors, processors, and output displays provide greater accuracy, automation, repeatability, and speed.

And with weighbridge software, it has become much easier to manage data and accounting. Newer software developments mean that weighbridge systems can be integrated into the company’s own internal software systems and provide more information to relevant parties and customers.

Weighbridge automation guarantees secured weighing and real-time reporting, and can be customised as required. Here are some of the benefits of automated weighbridges and how they contribute to revolutionising the supply chain.

Secure and reliable – Now, weighing can be done under CCTV surveillance with continuous photo/video capturing of vehicle and platform while recording weight. You don’t have to keep worrying and checking the weighing process.

Anti-theft Security Checks – Technology can help to eliminate fraud and theft. The anti-theft security check restricts human errors like fake weighing, double weighing of the same vehicle, manipulation in vehicle positioning, zero error, and verifies vehicle identity. Your entire weighing process will be more safe and accurate.

Operator-less and fast Weighing – With automated weighbridges, you can save labor cost as there is no need for an operator. Weighing is done through RFID (Radio Frequency Identification). By eliminating human interaction, it makes the weighing process faster.

Data Management – Weighbridges are equipped with data management software, which makes it easier to control and report the data. All the data is electronically stored and backed up so that you can easily access it when required. Furthermore, it also speeds the weighing process by reducing the documentation and formalities.

Volumetric Real-time monitoring – The weighing process can be monitored in real-time through the dashboard without being present in the weighing spot. You will get live details of the weighing process and can monitor each transaction.

Reporting – Report generation is also easier with an automated weighing system; virtually any reports can be drawn based on the information required, and delivered via e-mail.

Weighbridge truck scales are a valuable asset for all industries, They deliver a wide range of benefits, not limited to the supply chain. However, there are various types of weighbridge truck scales and software available. To get maximum benefits (better return on investment), it is essential to partner with an experienced weighbridge supplier who can ensure the weighbridge matches your requirements for both short and long-term.

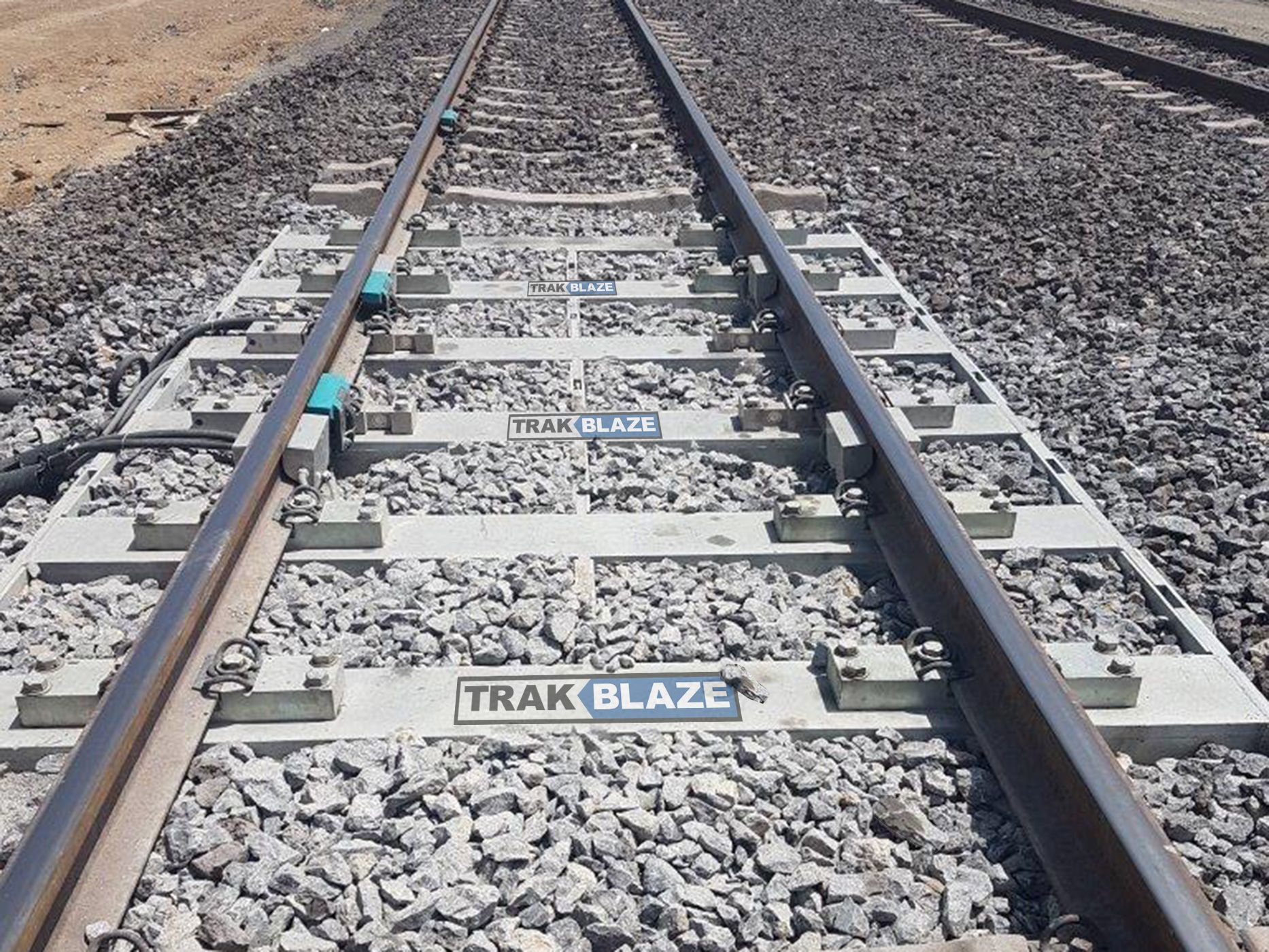

If you’re interested in improving your company’s supply chain by increasing productivity, reducing costs, improving safety and efficiencies, have a chat with one of Australia’s largest weighbridge manufacturers, Trakblaze. They’ll understand your needs and help you to choose the best weighbridge solution for your unique operational needs. Take advantage of their years of experience by contacting or by visiting their website, https://trakblaze.com/