Mobile Volumetric Scanner – A Easily Transportable And More Accurate Way To Get Your Load Volume

Monday, 22nd July

At a glance:

- Precision measurements and real-time analysis streamline bulk material management.

- Versatile application across industries like mining, construction, and logistics.

- Cost-effective solutions with easy installation and low maintenance.

- Empower businesses to optimise resources and drive sustainable growth.

Mobile Volumetric Scanners have come into the industry and begun to change the game. They offer an innovative, time and money-saving opportunity for mining sites and transportation. Volumetric scanners allow us to measure bulk materials loaded into trains or any other vehicle using imaging software, and they offer an automatic calculation without a hassle.

There is no doubt that traditional weighbridges do their job well, but now volumetric scanners are gaining popularity and becoming more valued by many industries worldwide.

Mobile Volumetric Scanner

The fantastic technology behind how volumetric scanners work is fascinating and efficient. When the vehicle passes the scan head, the volumetric scanner automatically identifies the type of the vehicle and records all the required measurements. The software collates all the data from the load and provides a 3D image within the report. During this process, manual labour is unnecessary, which is another reason mobile volumetric scanners are rising in popularity.

How Does a Mobile Volumetric Scanner (MVS) Work?

Automated Vehicle Identification

Mobile volumetric scanners utilise automated technology to identify the type of vehicle as it passes through the scan head.

Measurement Recording

Once the vehicle is identified, the scanner records all necessary measurements automatically without requiring manual intervention.

Data Collation

The software integrated with the scanner collects and collates all data related to the load, ensuring accuracy and efficiency in the process.

3D Imaging Capability

A notable feature of mobile volumetric scanners is their ability to generate 3D images within the generated report, providing comprehensive visual insights.

Elimination of Manual Labour

The entire scanning process is automated, eliminating manual labour, enhancing efficiency and reducing operational costs.

Rising Popularity

Mobile volumetric scanners’ convenience, accuracy, and labour-saving aspects contribute to their increasing popularity in various industries.

Features And Benefits Of Mobile Volumetric Scanner (MVS)

Zero Interference

Volumetric scanners offer an accurate and reliable performance regardless of weather conditions, as the operation is virtually conducted. The function is also not affected by variables like debris, moisture content, and uneven loads. They run smoothly without the interference of any external factors.

Accuracy & Efficiency

One of the most significant advantages of mobile volumetric scanners is that they quickly record accurate data while the vehicle is moving; hence, it is accurate and efficient.

User-friendly

Volumetric scanners are equipped with features like data storage, touchscreen operation, and connectivity with the outside world via the Internet, making these scanners easy to use. The operation of the scanner does not require expertise; even a little training will get the job done.

Real-time Data Analysis

Many mobile volumetric scanners offer real-time data analysis capabilities, allowing users to quickly assess vehicle dimensions and load characteristics, enabling timely decision-making and optimisation of operations.

Versatility

Mobile volumetric scanners are versatile tools that can be deployed in various environments and applications, ranging from transportation hubs to construction sites, offering flexibility and adaptability to diverse operational needs.

Improved Safety

By automating the scanning process, mobile volumetric scanners help improve safety by reducing the need for manual intervention in potentially hazardous environments, minimising the risk of accidents and injuries.

Regulatory Compliance

These scanners often come equipped with features that ensure compliance with regulatory requirements and standards, helping businesses avoid fines and penalties associated with inaccurate measurements or non-compliance.

Cost-effectiveness

Mobile volumetric scanners offer a cost-effective solution for businesses by streamlining operations, reducing labour costs, minimising errors, and optimising resource utilisation, ultimately leading to improved profitability.

Easy Installation And Maintenance

Mobile volumetric scanners do not require hard work to install, and they can be fitted effortlessly and can be relocated to any needed location. Also, they require low to zero maintenance, which saves time and, of course, money.

Applications of Mobile Volumetric Scanner (MVS)

Logistics and Transportation

Mobile volumetric scanners are essential for load management, dimensioning, and weight verification in logistics and transportation, optimising cargo space utilisation and ensuring compliance with regulations.

Warehousing and Distribution

In warehousing and distribution centres, these scanners facilitate inventory management, space optimisation, and order fulfilment by accurately measuring and recording the dimensions of goods.

Construction and Engineering

Mobile volumetric scanners assist in construction and engineering projects by aiding in site planning, material management, and progress monitoring through precise volume estimation and resource planning.

Mining and Quarrying

These scanners are crucial in mining and quarrying operations for stockpile management, volume estimation, and regulatory compliance, helping optimise material extraction processes and track inventory levels.

Port and Terminal Operations

Mobile volumetric scanners are used in ports and terminals for container handling, cargo inspection, and vessel loading, ensuring accurate measurement of container dimensions and compliance with shipping standards.

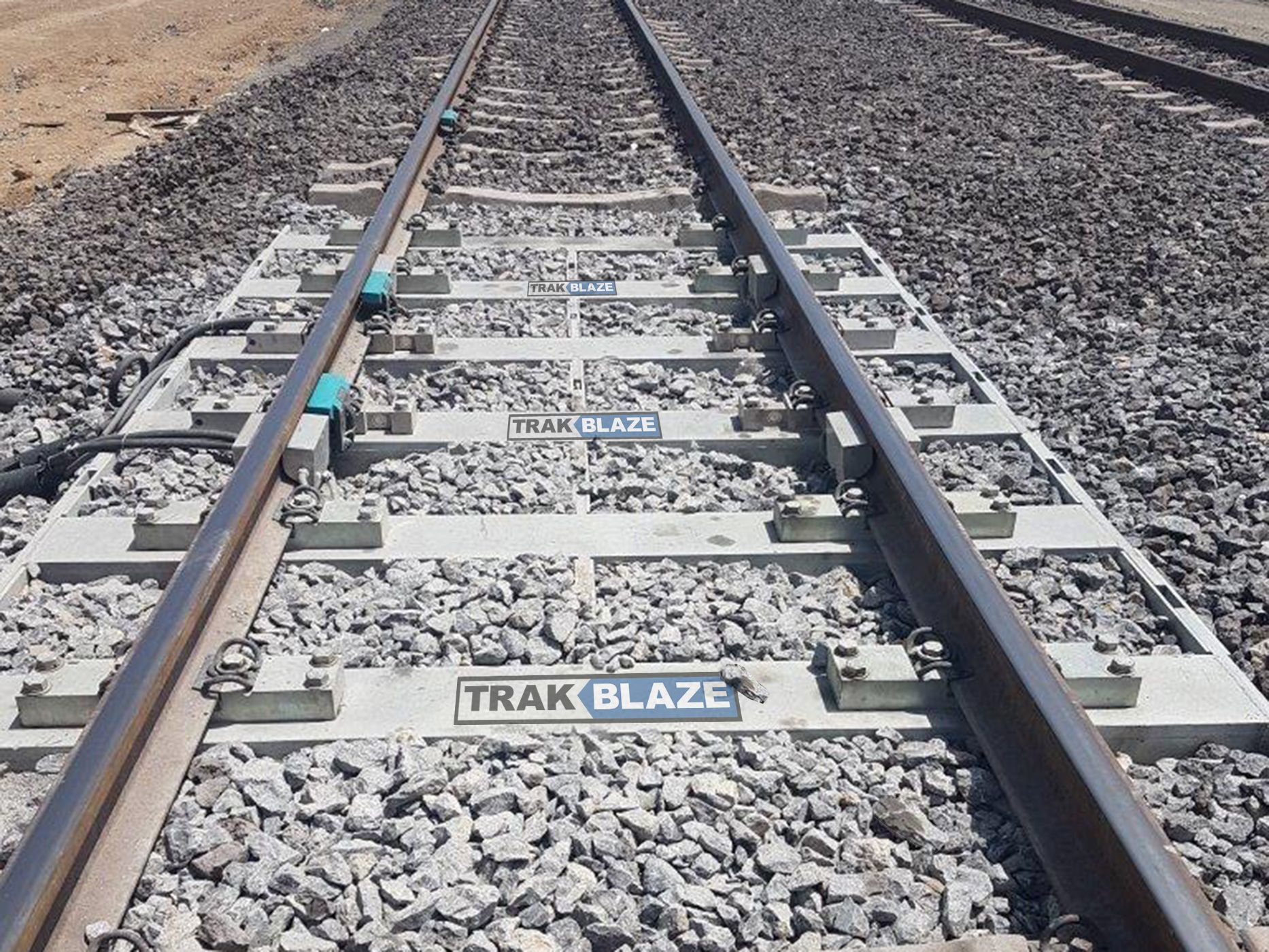

If you are struggling to find a volumetric scanner for your business, Trakblaze is the company you need to be looking at. Trakblaze supplies cutting-edge volumetric scanners, weighbridges, and weighing solutions across the mining, rail, aviation, and road industries. Their only aim is to offer a high-quality weighing system to their clients.

Trakblaze has been the market leader since it entered the industry 90 years ago. This has been possible because they invest in research, development, design and manufacturing to create a comprehensive range of top-class weighing and measurement equipment.

They ensure when you use their volumetric scanning system, you can be confident about its accuracy. By using Trakblaze’s volumetric scanners, your peace of mind is guaranteed. Contact Trakblaze for all your weighing queries; they offer the best solutions and can help you transform your business performance.

In conclusion, Mobile Volumetric Scanners revolutionise bulk material management, offering precise measurements and real-time data analysis. Their versatility spans industries like mining, construction, and logistics, streamlining operations, enhancing safety, and ensuring regulatory compliance.

With easy installation, low maintenance, and cost-effectiveness, these scanners empower businesses to optimise resources and drive sustainable growth in today’s competitive landscape. Embracing this technology is not just wise—it’s essential for staying ahead in the modern marketplace.

Why Overloaded Road & Rail Vehicles’ Are Dangerous And How To Avoid Them?

Wednesday, 17th July

At a glance:

- Unveil hazards associated with overloaded road and rail vehicles, from increased braking distances to compromised vehicle stability.

- Effective measures, like strict regulations to ensure road and rail safety and awareness, help in avoiding overloading.

- Businesses can use smart technological appliances like weighing scales to avoid overloading and prevent the loss associated with it.

When we travel by road or rail, there are a lot of different risks that come along. Whether it is a vehicle carrying people, equipment or products, the risk is universal.

One of the most common reasons for accidents in road and rail vehicles that are carrying equipment or cargo of any kind is overloading & unbalanced loads. While to some, overloading a vehicle might seem like a way to make more profit every time you are transporting goods, the risks here outweigh the benefits.

Overloading vehicles can cause accidents and derailment, leading to damaged road and rail infrastructure or even injuring a person and other property: it may seem as though it is not something for concern, but it definitely is. Not only could it cost millions to repair the infrastructure, but you would also damage the actual vehicle, which is a massive loss for the business owner, or you could risk someone else’s life.

If you overload the vehicle and don’t get into an accident or damage the vehicle, overloading can still carry a hefty fine and legal action if your vehicle carrying goods gets pulled over to have its weight limit checked. Overloading is both a safety and cost concern.

In this blog post, we will look at the various risks of overloading and how to overcome them.

Dangers of Overloaded Road and Rail Vehicles

Increased risk of accidents

Overloading your vehicles might sound like a profitable venture at first, but this is not the case. When you carry loads that outweigh the weight limit of your vehicle, it drastically increases the risk of accidents. When you overload your vehicle, the weight is not evenly distributed across the vehicle. As the weight is situated in the back of the vehicle, the front tyres touch the road under less weight compared to the rare tyres. This will result in steering difficulties.

An overloaded vehicle does not respond to steering input as quickly as it should, which may lead to an accident. Furthermore, it will take longer to build up and maintain speed and decelerate as well. The extra weight will increase the braking distance, and it will be trickier to slow down the vehicle, resulting in collisions with other vehicles or infrastructures on the road.

Overloading also exposes vehicles to an increased risk of rollover accidents. When you apply sudden brakes or over-steer an overloaded vehicle, the vehicle may roll over, further increasing the risks of accidents.

Infrastructure damage

Overloading of road and rail vehicles has serious effects on the road and rail infrastructure. An overloaded vehicle exerts more pressure on the road than normal vehicles. A frequent movement of overloaded cargo will make the asphalt tear down quickly, reducing the lifespan of roads or bridges.

In the case of rail transport, the overloading will impact the structural integrity of rail tracks. An overloaded train means more friction between the wheels and the tracks, which will impact the structural integrity of the tracks.

Furthermore, overloading is also associated with an increased risk of accidents. Thus, when accidents occur, the infrastructure in proximity and the transport infrastructure itself will be damaged.

Environmental impact

Overloading of vehicles or cargo has a severe impact on the environment. An overloaded vehicle consumes more fuel than normal, and more power is required to accelerate the vehicle. The increased fuel consumption results in higher carbon emissions. Furthermore, continuous overloading will result in wear and tear of vehicle equipment and road and rail infrastructure, which means excess use of raw materials and energy to process them. All of these will result in higher carbon emissions, thus having a negative impact on the environment.

Factors Contributing to Overloaded Vehicles

Economic Pressures on Transport Operators

Financial reasons are often the major cause of overloading vehicles. Overloading of vehicles will cut down the number of deliveries required for a job. The reduced number of trips will cut drivers’ wages and fuel consumption. This way, businesses can save money by overloading their cargo and increasing the profit margin.

Lack of Enforcement and Monitoring

When there is no proper monitoring and enforcement of laws regarding overloading, businesses will continue to overload their vehicles with an eye for a better profit. Inconsistent enforcement and monitoring practices contribute to a culture of non-compliance. Without robust oversight, overloaded vehicles can operate with impunity, endangering road and driver safety.

Inadequate Infrastructure and Weigh Stations

Insufficient infrastructure, including a scarcity of properly equipped weigh stations, makes it challenging to conduct accurate weight assessments and enforce regulations effectively. Existing facilities may be inadequate, given the growing demands of the transportation industry.

Inaccurate Weight Distribution Practices

Poor weight distribution practice by drivers and operators is another contributing factor to overloading. When the weight distribution across a vehicle is not equal, it means one part of the vehicle is overloaded while the other is not. Such inaccurate weight distribution practice will result in vehicle imbalance, compromising vehicle stability and road safety. Lack of awareness and education on proper weight distribution further exacerbates this problem.

How To Avoid Overloading

Regulation and Enforcement

Proper rules and regulations should be implemented to deter businesses from overloading their vehicles. If there are existing regulations on overloading, they should be enforced strictly, and related personnel should be made aware of them. Establishing clear guidelines on weight limits and load distribution will ensure a standardised approach across the industry.

Implementing stringent penalties for overloaded vehicles will also serve as a deterrent, promoting adherence to weight regulations. Fines, license suspensions, and vehicle impoundment can be effective measures. Enhanced enforcement measures, including increased inspections and penalties for non-compliance, can prove effective in avoiding overloading and its consequences. Regular audits and checks at weigh stations can also be effective on this front.

Education and Awareness

When you run a logistics, rail or mining company, you and the drivers are not the only people involved with loading. Various departments are engaged equally to prevent overloading, so every party involved should have some basic understanding of overloading and its consequences.

When they know the accurate weight & balance of the load and vehicle, there are fewer chances of overloading.

In several cases, overloading is the result of a lack of awareness. So, it is imperative to conduct comprehensive training programs to educate drivers and operators on proper loading practices, weight distribution, and the consequences of overloading.

Raising public awareness can also encourage businesses to avoid overloading. If a larger audience is made aware of the dangers of overloaded vehicles, it fosters a collective responsibility for road safety. Campaigns through media, community events, and digital platforms can be impactful.

Furthermore, collaborative efforts within the transportation industry can drive initiatives to promote responsible loading practices. Industry associations can play a pivotal role in implementing best practices regarding road safety and fostering a culture of compliance.

Embracing Smart Solutions like Weighing Systems

One of the best ways to avoid hazards caused by vehicle overloading is weighing them before getting them onto the road. The right weighbridge can help you to determine if your vehicle is overloaded or not.

Modern weighbridges are fast and accurate and can deliver your business’s essential weighing information before any of your vehicles hit the road. You might be wondering where you can purchase the best and most accurate weighbridges, and the answer is Trakblaze.

Trakblaze is a leading manufacturer of weighbridges for the road, rail, mining, and aviation industries. They offer both static and portable weighing systems for all areas. If you are looking for a weighbridge, get in touch with Trakblaze; with 90 years of experience, they will be able to offer you the best in the business.

In conclusion, addressing the issue of overloaded vehicles requires a multifaceted approach. By enforcing regulations, implementing stricter penalties, conducting comprehensive training programs, and promoting innovative weighing systems, we can collectively create a safer and more efficient transportation ecosystem. Proactive efforts from regulatory bodies, industry stakeholders, and the public are crucial for mitigating the detrimental impact of overloaded vehicles on our roads and infrastructure.

Importance Of Balanced And Configured Loads For Efficient Rail Haulage

Monday, 08th July

At a glance:

- Balanced loads ensure rail safety by preventing accidents and derailments.

- Efficient load configuration boosts operational efficiency and reduces costs.

- Proper management of the rail fleet enhances capacity and adaptability to cargo types.

Australia is a huge country. And its economy relies heavily on its ability to efficiently and effectively transport goods around the country – both short and long haul. Whether it’s imprinted manufactured goods or commodities for exports, our transport infrastructure and capital – trucks and trains – is essential to our economic productivity.

Whether transporting by truck or rail, a key factor to our national economic success and the profitable success of individual enterprises is the ability to use our transport infrastructure safely, optimally and profitably. Without those three things accounted for, our competitive advantage – as a nation and as individual companies – starts to fall away.

One of the key elements of optimising transport efficiency, maximising profitability and ensuring safety and compliance is the effective management of load configuration – both in terms of load spread and weight.

What is Load Balancing and Configuration?

Load balancing refers to the even distribution of cargo weight across the train. It ensures that each vehicle carries its share without overburdening one more than another. Configuration, on the other hand, involves arranging the cargo, optimising space utilisation and maintaining the train’s stability during movement.

By maximising payload, ensuring accurate and balanced load spread across axles and/or bogies and reducing overloads and poor load distribution, revenue is maximised, and maintenance costs are drastically minimised. It’s a fine balance, for sure, but it’s a critical balance to get right because getting it wrong causes a multitude of problems.

The Importance of Balanced and Configured Loads for Efficient Rail Haulage

Enhanced Safety

Safety in rail transport is significantly improved through balanced and configured loads. This meticulous approach to load distribution mitigates the risk of accidents by preventing excessive sway and reducing the likelihood of derailments. By ensuring that cargo weight is evenly spread across the train, operators can maintain a stable and secure environment, safeguarding both the freight and the railway personnel involved.

Prevents Derailments

Derailments, often resulting from uneven load distribution, pose a severe risk to rail safety and operational continuity. Balanced and properly configured loads help to evenly distribute the dynamic forces exerted on the track during transit, particularly in curves and inclines. This critical measure significantly reduces the risk of derailments, ensuring smoother and safer journeys for both goods and rolling stock.

Minimise Track Damage

Track longevity is crucial for the rail industry. Balanced loads ensure that the weight exerted on the rails is distributed evenly, preventing localised pressure points that can lead to track deformation and wear. This uniform distribution of load not only extends the life of the rail infrastructure but also maintains optimal conditions for safe and efficient train operations.

Improved Operational Efficiency

Optimised Fuel Consumption

Efficiency in rail transport is greatly enhanced by balancing and configuring loads, which optimises fuel consumption. By reducing the energy required to move a train, operators can achieve significant savings in fuel costs and lower the environmental impact of their operations. This approach contributes to a more sustainable and cost-effective rail transport system.

Increased Speed

The ability to maintain higher speeds safely is a direct benefit of balanced and configured loads. This efficiency reduces transit times, allowing for quicker deliveries and improved service reliability. Faster speeds also mean trains can complete more trips over a given period, increasing the overall capacity and effectiveness of the rail network.

Cost Savings

Reduced Maintenance Costs

A balanced and configured load minimises the wear and tear on both the track infrastructure and the rolling stock. This careful management of cargo reduces the frequency and severity of maintenance requirements, leading to substantial cost savings. Lower maintenance costs contribute to the overall financial health and competitiveness of rail operators.

Extended Infrastructure Lifespan

By preventing excessive stress on tracks and vehicles, balanced loads significantly extend the useful life of rail infrastructure and rolling stock. This not only defers costly replacements and repairs but also ensures a more reliable service over time. An extended lifespan of rail assets is crucial for sustaining the efficiency and economic viability of rail transport.

Higher Load Capacity

Maximising the available space through effective load configuration allows for the transportation of more goods in each journey. This not only optimises the revenue potential of each trip but also enhances the overall efficiency of the logistics chain. By increasing load capacity, rail transport can better meet the demands of a growing economy.

Maximised Cargo Volume

Efficient load configuration, such as the use of intermodal containers, enhances the volume of goods that can be transported. This optimisation leads to higher productivity and efficiency in rail haulage, enabling the industry to handle an increasing volume of freight. Maximising cargo volume is essential for meeting the logistical challenges of modern commerce.

Adaptability to Different Cargo Types

The flexibility to accommodate various types of cargo is a significant advantage of balanced and configured loads. This adaptability ensures that rail haulage remains a versatile and reliable option for transporting a wide range of goods, from bulk commodities to high-value products. Adapting to different cargo types is key to fulfilling the diverse needs of the global market.

In a report prepared for Infrastructure Australia, PWC identified payload and axle load management as a critical element in making rail freight transport economically feasible, particularly in relation to short hauls in and around major ports.

The report noted that maximising tonne axle loads in order that they are fit for purpose to attract and retain freight volumes results in improved line haul economics and reducing the potential distance at which short haul rail freight works.

In Australia’s highly regulated freight transport environment, succeeding in finding these kinds of efficiencies means that freight and logistics managers need to be able to accurately measure, record, analyse and communicate the most minute detail about freight loads right down to the individual bogie load carrying statistics. In high volume transport environments, where the road freight alternative might seem very appealing and easy, this can be a critical point of difference.

And the same advantages apply on longer haul regional freight routes, although the drivers are slightly different – particularly because, while the opportunities to improve tonne axle loadings on regional rail networks is naturally greater, the drivers for investment are lower due to the reduced much lower freight transport densities – so getting it right is critical to the investment thesis.

Weighing and Balancing Systems

There are a variety of weighing and balancing systems that are specific to managing

rail haul vehicles, but importantly it is essential to invest in a highly accurate, reliable and industry proven system that is purposely designed for the task.

Trakblaze have one of the largest ranges of rails weighing and balancing products and is also synonymous with only manufacturing quality, reliable and highly accurate rail systems.

Getting the basics right benefits us all, from producer to consumer.

To maximise the freight opportunities from rail, operators need to measure, understand and manage their rail fleet from the driving infrastructure right through to each individual bogie’s balance and configuration.

Rail Scale Benefits For The Mining Industry

Tuesday, 02nd July

At a glance:

- Trakblaze’s rail scales revolutionise safety, productivity, and profitability in the mining industry.

- Our systems ensure accurate weighing, preventing overloading fines and optimising load management.

- From low-speed to high-speed solutions, Trakblaze offers versatile rail-scale technology for various applications.

In the competitive and demanding world of the mining industry, efficiency and safety are paramount.

The adoption of advanced technologies is not just a trend but a necessity.

Among these innovations, rail scales present a transformative opportunity for mining operations.

This blog explores rail scale solutions’ critical benefits, particularly safety, productivity, and profitability enhancements.

We will delve into Trakblaze’s contributions to this sector, highlighting their MTW and INFINITY HS/ LS rail scale systems.

Rail Freight in Australia’s Mining Sector

Rail freight is essential to Australia’s largest mining commodities sector.

It provides the most effective mode of transport for delivering maximum transport capacity for bulky goods, whether transport is required from mine to port or mine to production facility.

According to Austrade, Australia leads the world with respect to heavy haul, intermodal freight rail expertise and capacity. Again, according to Austrade, Australia’s rail freight system runs the world’s heaviest and longest haul trains – with axle loads up to 40 tonnes and train lengths of more than 2.5 kilometres.

Weighing is synonymous with the rail industry, regardless of which country you travel through.

It is a crucial element when balancing rail vehicles and even more so when it comes to the balancing of bogies.

For rail freight in Australia’s mining sector, with the world’s largest and heaviest freight trains operating, weighing is an even more critical operation.

As with any commodity, accuracy, efficiency, and productivity are absolutely critical in all parts of the logistics and supply chain processes.

That means that the rail weighing process must be capable of delivering efficient solutions that minimise the productivity impacts (and therefore cost) of delivering mining freight to a port or production location.

Rail operators need to be confident that their rail scales deliver highly accurate outcomes in the most time and labour-efficient manner.

This ensures, firstly, the highest quality safety outcomes and, secondly, confirms productivity and profitability benefits.

Benefits of Rail Scale in the Mining Industry

Safety

The mining industry, known for its rigorous safety standards, significantly benefits from rail scales.

These systems ensure that loaded rail wagons maintain optimal weight distribution, reducing the risk of accidents due to overloading or imbalanced loads.

Accurate weight measurements are crucial for maintaining rail integrity and preventing derailments, thereby safeguarding both employees and the environment.

Productivity

Efficiency is the backbone of productivity in mining operations.

Rail scales streamline the loading process, allowing for real-time weight measurements without the need for additional stops or rerouting to static scales.

This seamless integration into the rail system minimises downtime and enhances the speed at which materials are transported from the mine to processing plants or ports. It ensures that productivity targets are met or even exceeded.

Profitability

Profit margins in mining are closely tied to operational efficiency and cost management.

Rail scales offer a direct path to improved profitability by ensuring accurate billing and inventory management.

Avoided Overloading Fines

The precise measurement of goods transported ensures that companies are neither giving away products for free nor receiving penalties for shipment discrepancies. This accuracy supports better financial forecasting and resource allocation.

Trakblaze’s Rail Scale Solution for Mining Industry

MTW (Mobile Train Weigher) system

The MTW (Mobile Train Weigher) system from Trakblaze is a pioneering solution designed to bring the scale directly to the train. The Mobile Train Weighing (MTW) system can also be configured as a Multiple System (MTW-MS).

This innovative system allows for the static weighing and spot-checking of rail vehicles anywhere, anytime, emphasising flexibility and convenience in train weighing and balancing.

Features:

- Wired or Wireless System: Offers flexibility in setup according to the operational environment.

- User-Friendly Operation: Designed for ease of use with a simple installation process.

- Quick Installation: Can be set up by two persons in approximately 30-45 minutes.

- Transportability: Its portable design makes it easy to move and use across different locations.

- Load cell Based System: Ensures accurate weight measurement for each axle and the total train.

- Connectivity: Supports up to 8 MTW bases for comprehensive train analysis.

- Versatile Compatibility: Fits any gauge of track and most rail sizes, enhancing its applicability.

- PC-Based Controller: A modern interface for managing and recording weight data which can be sent to any devices via internet

Benefits:

- Flexibility in Train Weighing and Balancing: The system’s mobile nature allows for on-site train weighing, offering unparalleled convenience.

- Minimal Downtime: Its design ensures that track usage is barely interrupted during installation, maintaining operational continuity.

- No Need for Costly Infrastructure: Eliminates the requirement for expensive civil works for setup.

- Calibration Simplicity: Comes pre-calibrated, removing the need for a test train or transport of test weights.

- Accuracy and Reliability: Provides precise weight measurements, enhancing safety and operational efficiency.

The MTW MS system exemplifies Trakblaze’s commitment to innovation in the rail industry, providing a versatile and reliable solution that addresses the unique challenges the mining sector faces.

INFINITY-LS Train Weighing System

The INFINITY-LS Train Weighing System by Trakblaze is designed for low-speed weighing in-motion of up to 15km/h. This makes it an ideal solution for various applications including mine loadouts, industrial plants, and more.

This weighbridge system is composed of electronic weigh sleepers and dummy sleepers.

These components form a solid structure that includes accessories, a control cabinet, and a PC with specialised train weighing software.

Features:

- Electronic Weigh Sleepers: Provide accurate weight measurements.

- User-Friendly Software: For easy operation and data management.

- Quick Installation: Typically 1 to 2 days, with minimal site preparation needed.

- Remote Access: Weight data can be accessed from any location via the internet.

- Flexible Installation: Can be installed one wagon length out from the loadout.

Benefits:

- Accurate Load Management: Prevents overloading and ensures optimal wagon loading.

- Operational Efficiency: Enhances loading operations by providing real-time weight data.

- Minimal Downtime: Designed for quick installation and minimal track downtime.

- No Major Infrastructure Changes Required: No need for rail cutting, welding, or grinding.

- Reliable and Durable: Built to withstand tough conditions while providing precise measurements.

This system offers a practical and efficient solution for accurate train weight measurement, crucial for improving safety, efficiency, and profitability in operations requiring rail transportation.

INFINITY- HS Train Weighing System

The INFINITY HS Train Weighing System is the high-speed sibling – a rail weigh-in motion train weighbridge, capable of weighing trains at speeds of up to 80kph, dependent on track/site conditions and test train/rolling stock, using highly accurate and reliable load cell technology.

It generally consists of six electronic weigh sleepers and twelve dummy sleepers that are braced together to form one solid structure underneath existing track.

This unique bracing technology provides maximum stability to help eliminate the impact of weight transition, greatly enhancing accuracy.

The infinity Range includes accessories, control cabinet and PC train weighing software with weighing results accessible from any location via the internet.

The INFINITY rail weighbridge systems deliver multiple benefits to the mining industry, including:

- Accurate and reliable load cell-based weighing system

- No requirement for rail cutting, welding or grinding

- Minimal installation track downtime

- All parts easily interchanged in under 30 minutes

- Ability to be used on curved track for speeds up to 5 kilometres per hour.

- Temperature compensated

Rail workshop weighing system from Trakblaze

TRAKMATE

TRAKMATE is a rail workshop weighing and balancing system designed by Trakblaze.

It is tailored for the mining, railroad, industries, offering a sophisticated solution for precisely weighing and balancing rail vehicles.

Features:

- Simple installation process.

- Compatible with all rail types and gauges.

- Heavy-duty construction with overload protection.

- Can accommodate any wheel weight combination.

- Temperature compensated for consistent accuracy.

- Cost-effective solution for rail weighing needs.

Benefits:

- Ease of Installation: Ensures that the system can be quickly and easily set up in various workshop environments.

- Versatility: Its compatibility with all rail types makes it a universal solution for different rail vehicles.

- Durability: Designed to withstand heavy use, ensuring longevity and reliability.

- Accuracy: Provides precise weight measurements under different conditions, aiding in effective vehicle maintenance and safety.

- Cost Efficiency: Offers a value-driven approach to high-precision rail weighing and balancing, reducing operational costs.

The TRAKMATE system exemplifies Trakblaze’s innovation in rail vehicle maintenance, offering a comprehensive solution that enhances efficiency, safety, and cost-effectiveness in rail workshop operations.

The integration of rail scales into mining operations heralds a new era of efficiency, safety, and profitability.

As demonstrated by Trakblaze’s MTW, INFINITY HS/LS, and TRAKMATE systems, the adoption of such technologies provides a competitive edge.

It aligns with the industry’s push towards more sustainable and responsible mining practices.

The benefits of rail scales extend beyond immediate operational improvements, offering long-term value through enhanced safety protocols, increased productivity, and improved profitability.

For mining companies looking to thrive in an increasingly challenging global market, investing in rail-scale technology is not just an option but a strategic necessity. Contact Trakblaze today!