Technology Driving Operational Efficiencies For Load Management And Weighing

Technological developments are creating significant improvements in the utility of weighing systems. While the basic technology of weighing itself hasn’t changed much, innovations which link weighing systems with other technology are creating a wealth of new opportunities for businesses to improve their efficiency, compliance and profitability.

In an increasingly interlinked world, where goods transport is critical, weighing systems are an essential part of the supply chain. However, these new technological innovations mean that manufacturers and processors, transport and logistics companies, traders, and receivers – as well as regulators – can increasingly get access to better quality, almost instantaneous information and even link it back through the supply chain to point of production, even potentially identifying specific vehicles that have transported the product.

What it all boils down to is that customers expect these innovations to deliver improved profits, better compliance with regulatory requirements, safety and operational efficiencies.

Some of the most important innovations have been those that allow the easy and automatic capture of real time data which can be made accessible to a wide range of users, locally or remotely, as it is collected. This integration of IT systems with weighing systems facilitates informed decision-making as it’s required, rather than having to rely on investigating a non-compliance or incident in order to improve the way things are done.

Systems integration also enables companies to continuously, reliably and remotely track productivity and performance, whether it’s in mining, agriculture, waste collection, goods transport or any of a wide range of applications. Margin for error is significantly reduced, particularly human error. Transport resources can be optimally allocated and key compliance and performance measures, such as gross and net tares and individual axle weights can be monitored constantly.

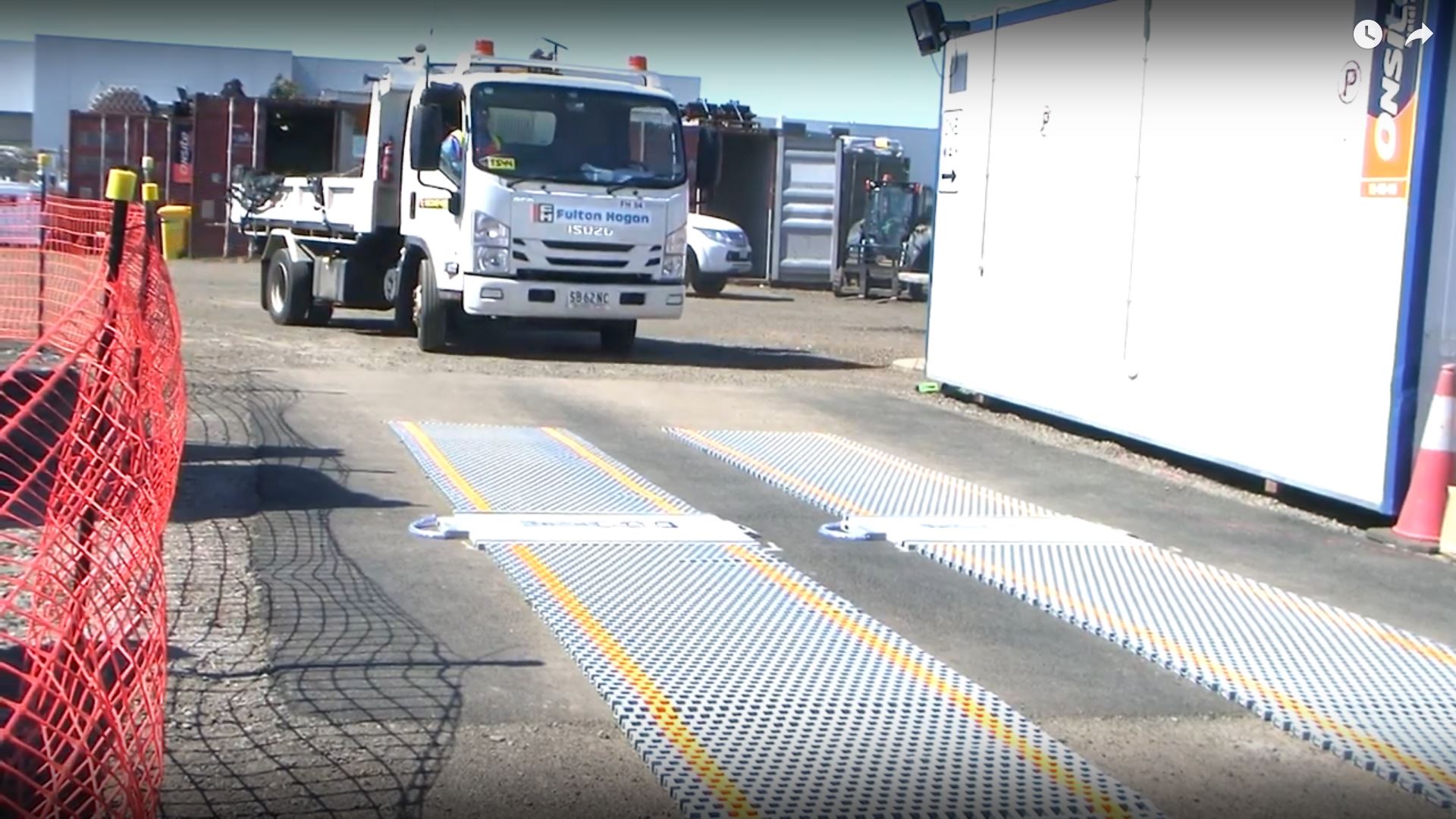

The ability to link weighbridge data with individual vehicles using unique identification systems, whether it’s Automatic Number Plate Recognition (ANPR) or adds yet another element of sophistication to improve the ways in which weight data is captured, communicated and used for real time analysis and decision-making.

Ultimately, companies and organisations that need to capture weight are doing it for a reason. Accurate load measurement, streamlined data capture and minimising error are all essential to keep the supply chain moving efficiently and effectively. And purchasers of weighing systems expect an innovative technological solution that is fast, efficient, accurate, functional, affordable and contributes to their performance on profit, safety and compliance.