- Industries

-

-

Rail infrastructure serving the farming and food production industries: four powerful diesel locomotives work a loaded grain train through rolling hilly landscape on way to port. In the distance are a range of hills and a red railway signal. ID and Logos edited. - Rail

- Trakblaze delivers over 95 years of precision in rail weighing and balancing to keep trains safe, accurate, and reliable.

-

- Road

- Trakblaze ensures road safety and compliance with precision truck scales and weighbridges backed by 95 years of expertise.

-

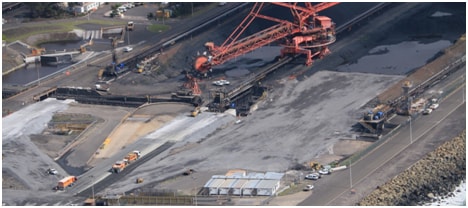

- Mining

- Trakblaze delivers precise weighing solutions for mining trucks and rail vehicles, ensuring maximum efficiency and compliance.

-

- Aviation

- Trakblaze enhances aviation safety with real-time aircraft weighing systems used before take-off, along with portable aircraft scales for flexible, MRO or on-the-go operations.

-

-

- Product

-

-

- Portable Scales

- TRUCKMATE

Portable Truck Scale - TRUCKMATE LITE

Ultra Low-profile Portable Truck Axle Weigher - FORCE 03

Heavy duty portable mining truck scale - FORCE 05

Static & dynamic portable mining truck scale - FORCE 06

Portable mining truck scale - AVIATOR

Portable Aircraft Weighing System - AVIATOR LITE

Portable lite aircraft scale

- TRUCKMATE

-

- Insights

- About Us

- Enquire Now