At a glance

- Accurate weighing systems are not just about compliance; they are linchpins for financial stability.

- They help avoid underloading and overloading, preserve your profit margins, and prevent excess fuel consumption.

- The accuracy of your weighing scale hinges on various factors, from load cell calibration to environmental influences.

- Choosing a high-quality weighbridge, installing it in a stable environment, regular cleaning, and meticulous calibration are crucial steps in ensuring precise results.

Weighbridges or weighing scales are the tools that allow transport companies and operators to ensure that their transport vehicles are within the industry standard weight limit before sending them out onto the road.

These tools ensure your business is compliant with all government regulations surrounding the weight of your vehicle and the safety of your drivers. Thus, the weighing system is often seen as the heart of transport and logistics businesses, and having an accurate and reliable weigh scale is vital to your business’ success.

The accuracy of your weighing scale is a crucial factor in keeping your transport and logistics business profitable. If your weighing scale is not accurate, there is no point in having one. So, the most important thing you have to consider when purchasing the weighing system is the quality of the scale.

However, even with a high-quality weighing scale, there are several factors you should consider that affect the accuracy of your scales. To ensure your weighing system is performing accurately, you should choose components that suit your application and take steps to control the effects of load cells, load factors, and environmental factors that have an impact on the weighing systems.

In this blog post, we will shed light on the importance of accurate weighing systems, factors affecting the accuracy, and how to ensure the accuracy of your weighing scales.

Importance of Accuracy in Weighing Systems

Load weight (the weight carried by a vehicle) is a crucial aspect of transport and logistics operations. Failing to maintain proper load weight leads to overloading and underloading, which leads to substantial financial loss and safety risks.

However, businesses can tackle the problems arising from inappropriate load weight by using accurate weighing systems.

Here’s why you should focus on the accuracy of your weighing scales:

Financial Considerations

The primary reason why trucking companies and other transport businesses should focus on getting accurate weighing systems is to foster robust finances. The lack of accurate weighing systems leads to inaccurate load weighing, which leads to problems like underloading and overloading. These problems have a serious impact on the profit margin.

For example, when you underload your trucks, you reduce your potential for profit from a job. The underloading will force you to run more loads, resulting in excess fuel consumption, transport charges, and vehicle maintenance costs. Ultimately, the profit margin from a transport job will be drastically reduced.

On the other hand, overloading can lead to the vehicle and load damage. In both cases, whether you have damaged goods or vehicles, it will cost money to cover them. Furthermore, there are strict weight regulations involved in heavy haulage transport. Failing to adhere to those weight restrictions will lead to substantial fines, which again will dent your profit margin.

Safety Concerns

Problems arising from underloading and overloading are not only limited to financial losses. They will also contribute to the compromised safety of drivers and vehicle operators and the goodwill of your business. When you underload or overload your trucks, there will be an improper distribution of load across the vehicle. This will increase the risk of accidents while on the road.

Factors Influencing Accuracy of Weighing Systems

Various environmental and human factors can impact your weighbridge’s accuracy; some of these are out of your control, while others aren’t.

Here are the factors that can affect the accuracy of your weighing system.

Load Cell Accuracy

The load cell (also called a load sensor or transducer) is the major weighing component that interprets the load’s mechanical force and converts the mechanical force into an electrical signal.

The load cell is the major component of any weighing system. The malfunctioning of the load cell will result in inaccurate weight readings.

Some of the elements that you should be familiar with to understand how load cell functions are response time, nonlinearity, creep, hysteresis, and temperature.

Response time refers to the time it takes for a load cell to settle and provide the correct reading.

Nonlinearity is the maximum difference of a load cell’s calibration curve from a straight line.

Creep is the change in load cell output over time when a load remains on the cell for a long time.

Change in temperature also leads to inaccuracy of weight. As the temperature rises, the wire resistance also increases, causing the voltage to drop, which leads to the scale controller displaying the incorrect result.

The accuracy of load cells is affected by several factors, for example, when they are not properly calibrated, the use of low-precision applications, and the physical condition of load cells.

Load Factors

Another factor that causes inaccuracy in the weighing system is the load itself and the way it is applied and supported. An improperly applied load, such as a twisting load, may result in inaccurate weight measurement.

Also, while measuring the loads, it is important to avoid uneven distribution of load across the weighing scale. Uneven load distribution results in measurement errors.

Ensuring drivers go slowly to prevent sudden changes in load and ensuring the mounting hardware is appropriately functioning are a few things you can check on when analysing load factors.

Environmental Factors

Environmental factors like wind loading, shock loading, vibration, large temperature changes, and pressure differentials are likely to produce errors in the load cell signal.

Wind Loading: Weighing systems can sometimes be affected by air movement created by air conditioners or air ducts.

Shock Loading: Suddenly, adding heavy materials to the weighing system can damage the system and the load cells.

Vibration: Vibrations from nearby equipment can be interpreted by load cells as additional force and provide inaccurate output.

Unclean Scale: The weighing scale may receive pressure from the dust or build up under the scale. To avoid this, the scale must be clean.

Measures You Can Take to Ensure Accuracy

Here’s how you can commit to ensuring the accuracy of your weighing systems:

Install Weighbridges In Area Where The Environment Is Stable

Suppose you operate your business in an area where there are extreme environmental changes or where there are extremely hot or cold locations. In that case, you need to create an area where these influences won’t impact the weighbridge.

While this might not be possible every time, if you are having a problem identifying the correct place for your weighbridge, your supplier can help you find a way to reduce the impact of environmental changes on your weighbridge.

Buy High-Quality Weighbridge

Choosing a high-quality weighbridge is also an important start. A low-quality weighbridge will not deal well with weather fluctuations, showing inaccurate results even in minor temperature changes.

Weighbridges that use the latest technology have a temperature compensation system, making sure the results are accurate even if the temperature fluctuates under a certain range.

Weighbridge Cleaning

Debris and moisture build-up around the weighbridge can also create problems – whether it’s dirt, ice, snow, or rain; these can cause wear and tear to any weighbridge. Any weighbridge operator should also be sure to clean their weighbridge regularly and the drain the site – weekly would be best.

Calibration Of Weighbridges

Calibration is an essential aspect of having an accurate weighbridge. It needs to be done every time the weather or the season changes. The location, weather, and placement of the weighbridge should be taken into consideration during calibration.

When calibrating your weighbridge, it should be compliant with the necessary government rules and regulations.

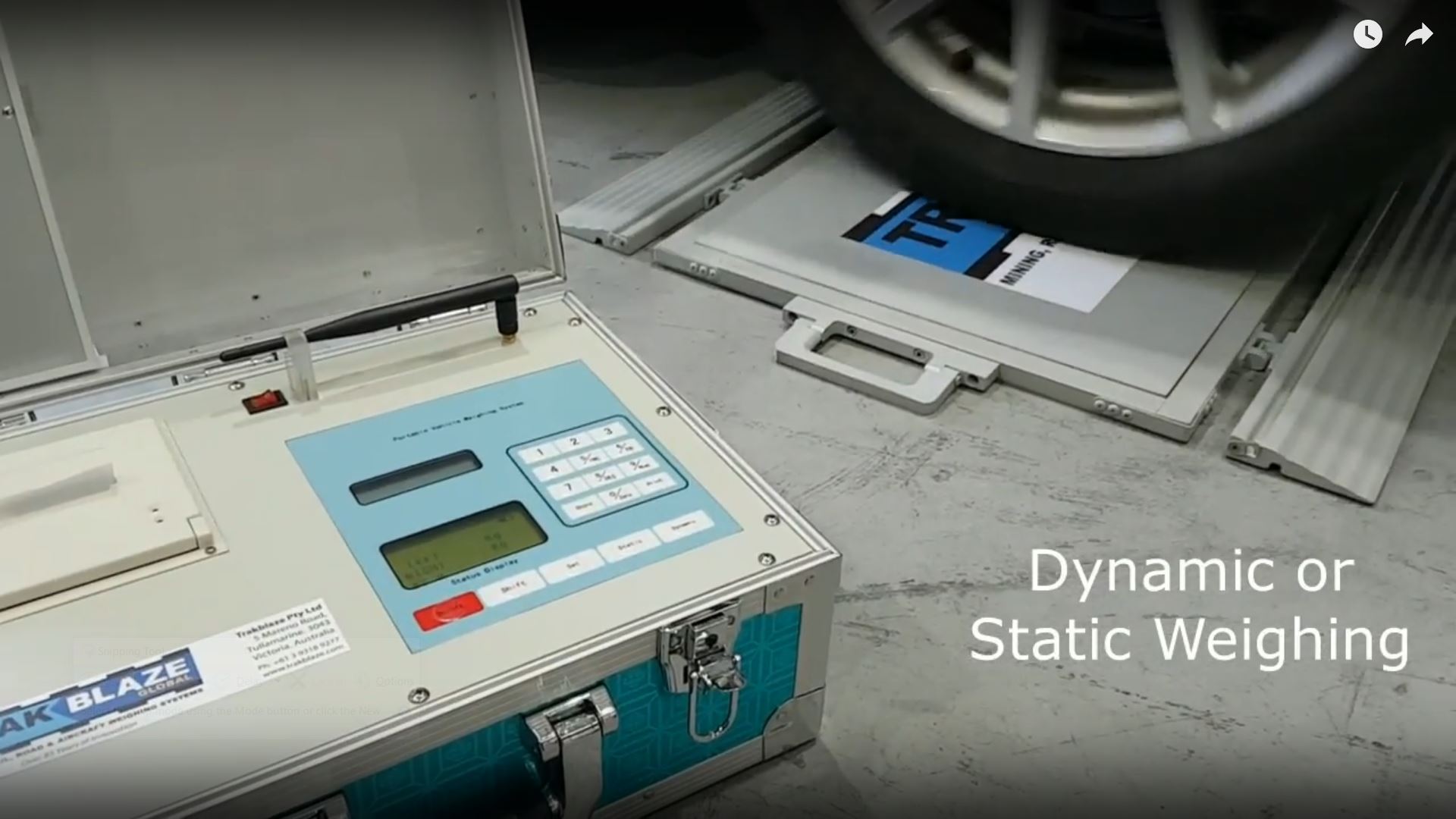

If you are looking for the best weighbridges on the market, consult with Trakblaze. We are a leading static & dynamic weighbridge manufacturer company in Australia and internationally with a service record of 90 years and counting. Our expertise lies in weighbridges for the road, rail, mining, and aviation industries.

We sell the most comprehensive range of weighing solutions for trains, trucks, mining, and aircraft worldwide. We have an extensive product range, including truck scales, weighbridges, mobile train weighers, volumetric scanners, and balancing systems.

Trakblaze strives to manufacture the most technically advanced scales that promise to deliver accurate results. If you are looking for high-quality weighing systems, contact Trakblaze. Get a free quote today.

In conclusion, the significance of accurate weighing systems in the transport and logistics industry cannot be overstated. The financial implications of underloading and overloading, including increased fuel consumption and maintenance costs, underscore the need for precision in load measurements.

Safety concerns also arise from improper load distribution, posing risks to drivers and vehicles. Understanding the factors influencing weighing system accuracy, such as load cell performance, load factors, and environmental conditions, is crucial.

To ensure accuracy, businesses must invest in high-quality weighbridges, regularly clean and calibrate their systems, and consider environmental stability during installation. Trakblaze, with a 90-year service record, stands as a reliable partner for top-notch weighing solutions.

Choosing Trakblaze, a reliable weighing system company with over 90 years of experience, ensures adherence to government regulations and the acquisition of technically advanced scales for accurate results, safeguarding the success and profitability of your transport and logistics endeavours. Let’s elevate your weighing system standards with Trakblaze.