At a glance

- Explore the revolutionary impact of volumetric scanning in mining and rail industries.

- From accurate measurements to real-time reporting, load optimisation, and environmental benefits.

- Discover how this technology streamlines operations, enhances safety, and contributes to cost-effective, efficient practices.

Volume scanning is becoming the new mining and rail industry standard as a reliable system when shifting bulk materials. The mining and rail industry is all about efficiently transporting materials from one place to another, and measuring these loads accurately is a crucial part of improving the revenue and productivity of said industries.

Most of the mining, civil construction, and quarrying industries embrace volumetric scanning as it provides highly accurate measurements and information-rich reports.

Gone are the days where getting a load measurement, involved lots of manual labour and guesswork including weighing the loads and converting them to volume. However, all of these industries now want a more precise and quick way to get the most accurate measurements, that will ultimately lead to the best outcomes and generate higher revenue.

Why Volumetric Scanning?

Revolution in Measurement Techniques

With a combination of modern software, new designs, and scanning specifications, volumetric scanning had revolutionised the way in which measurements of load are taken. Volumetric Scanning is a real alternative to weighing and provides accurate, reliable measurement data.

Ease of Installation and Use

Unlike permanent full draft weighbridges, volumetric load scanners don’t require extensive site work for installation, and they are effortless and quick to install.

Flexibility and Accuracy

Volumetric scanners can be used in smaller sites as a cost-effective mobile unit. However, this modern weighing system is also ideal for multi-site operations. You can easily speed up the measurement process while getting real-time, highly accurate data of all the loading locations.

Major Benefits

The major benefits on volumetric scanning is highly accurate measurements, improved work-flow, minimises human error, real-time scanning and reporting, load optimisation with 3D profiling and more.

Highly Accurate Measurements

Volumetric scanners ensure a highly accurate measurement as it uses an innovative, drive-through, non-contact scanning system. It scans an empty truck and stores its data in a database. Once the truck comes to load, a volumetric scanner evaluates the difference between an empty and loaded truck to calculate the load volume. It also looks at moisture content, loading variations, and compaction which can result in an inaccurate reading when other systems are used.

The system completely eliminates any false load counting that could be caused by human error.

Real-time Scanning And Reporting

Enhanced Payload Efficiency

One of the key advantages of volumetric scanning is its ability to optimise payload efficiency. By accurately measuring the volume of materials, companies can ensure their vehicles are neither over nor under-loaded, thereby maximising the efficiency of each transport.

Immediate Feedback

Getting immediate feedback on a load is vital for all mining and rail industries. It has the ability to stop any overloading from occurring, or any underloading issues, that can risk revenue being lost.

Advanced Software Capabilities

With the modern software used in volumetric scanning, now you can get real-time scanning and reporting before it’s too late.

Rapid Reporting

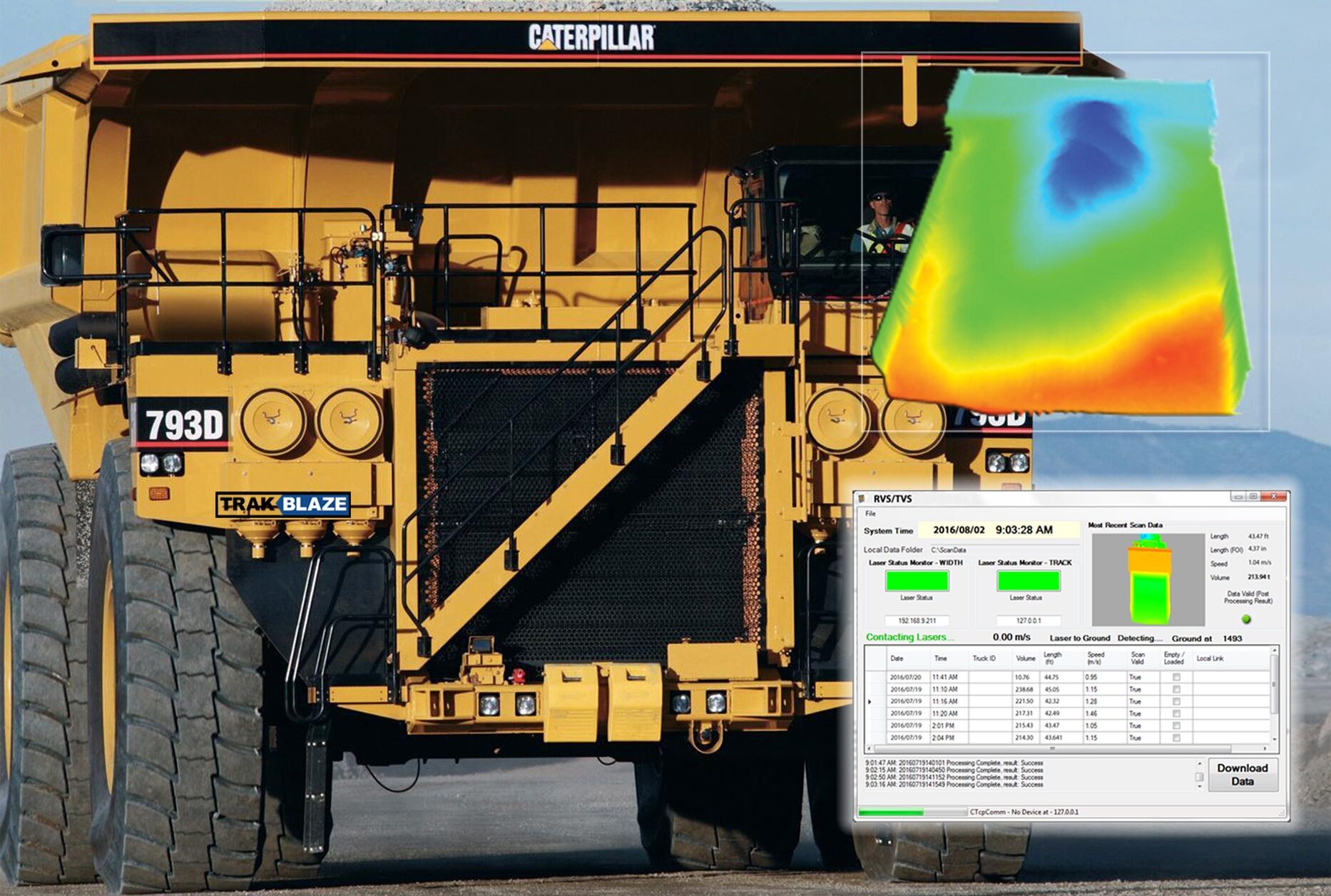

Once the truck/rail passes through the scanner, the software auto-scans, and in less than 10 seconds it reports on the data with a calculation of critical production parameter.

Load Optimisation with 3D Profiling

The primary goal of any weighing system is to optimise the load. The advanced software implemented in the volumetric scanner makes load management easier for operators and businesses alike.

To enhance the load management, the volumetric scanner provides a 3D volume profile of each load which will help to view the load position, carry back, and material compaction. As a result, truck and rail load capacity are fully utilised considering safety factors, overloading, or underloading.

Versatile Applications

Primarily used in mining, construction, industrial, and agricultural sectors, these systems are ideal for any operation that requires precise load measurements. From tracking the amount of material moved in a mining operation to ensuring agricultural products are transported efficiently, the versatility of these systems is unmatched.

Environmental Benefits

In today’s world, where environmental concerns are paramount, volumetric scanning helps in reducing the environmental impact of transportation. By optimising loads, it minimises the number of trips required, leading to lower fuel consumption and reduced carbon emissions.

Improved Operational Workflow

Incorporating these systems into daily operations streamlines workflow. With their ability to provide quick and accurate measurements, they reduce the time trucks spend on scales. Thereby increasing the throughput of vehicles and enhancing overall operational efficiency.

Cost-Effective Solution

Beyond the initial investment, volumetric scanners prove to be a cost-effective solution in the long run. Their low maintenance requirements mean reduced ongoing costs. While, the accuracy and efficiency they provide can lead to significant savings in operational expenses.

Safety Enhancements

By ensuring accurate load distribution, volumetric scanners enhance vehicle stability, reducing the risk of accidents due to overloading or improper loading. This not only ensures the safety of the transport but also contributes to the overall safety of the operation.

In summary, volumetric scanning systems are more than just an alternative to traditional scales. They are a comprehensive solution that brings efficiency, accuracy, cost-effectiveness, and environmental sustainability to the forefront of industrial and commercial transportation. The adoption of this technology is a step towards smarter, safer, and more efficient operational practices.

Implementing Volumetric Scanning with Trakblaze

If you are looking into introducing the use of volumetric scanning to measure truck or rail vehicles, with over 90 years of experience in weighing industry, Trakblaze now offers truck volumetric scanner (TVS),Rail volumetric scanner (RVS) and Mobile Volumetric Scanner (MVS). Volumetric scanners can be integrated with weigh-in-motion scales and work collaboratively to give better insights into your loads. If you are looking for more information, visit the Trakblaze website, in order to find out more, and discover the best weighing and measurement solutions, for your business.