At a glance

- Train weighbridges are essential for accurate weight measurement in railway logistics.

- Portable train weighbridges offer flexibility and mobility, making them suitable for temporary or remote locations.

- Static train weighbridges provide stability and durability for high-volume operations. Choose the right weighbridge based on your specific needs and circumstances.

Train weighbridges play a vital role in providing reliable weight measurement of trains and their cargo. The system ensures that rail vehicles and wagons are balanced and safe by giving accurate weight data. Similar to truck scales, a rail weighbridge is designed to avoid overloading during the transport of products, prevent damage to rolling stock, and minimise load impact on the track. Overall, train weighbridges are crucial in promoting operational efficiency, cost-effectiveness, and safety in transporting goods by rail.

They are essential for various industries, ensuring compliance with safety regulations, facilitating efficient logistics, and enabling accurate billing and revenue calculation. While portable and static train weighbridges effectively convert the track into a weighing scale without interrupting operations, they work differently. Today, we will explore the key differences between portable and static train weighbridges, shedding light on their unique features, advantages, and applications:

Portable Train Weighbridges

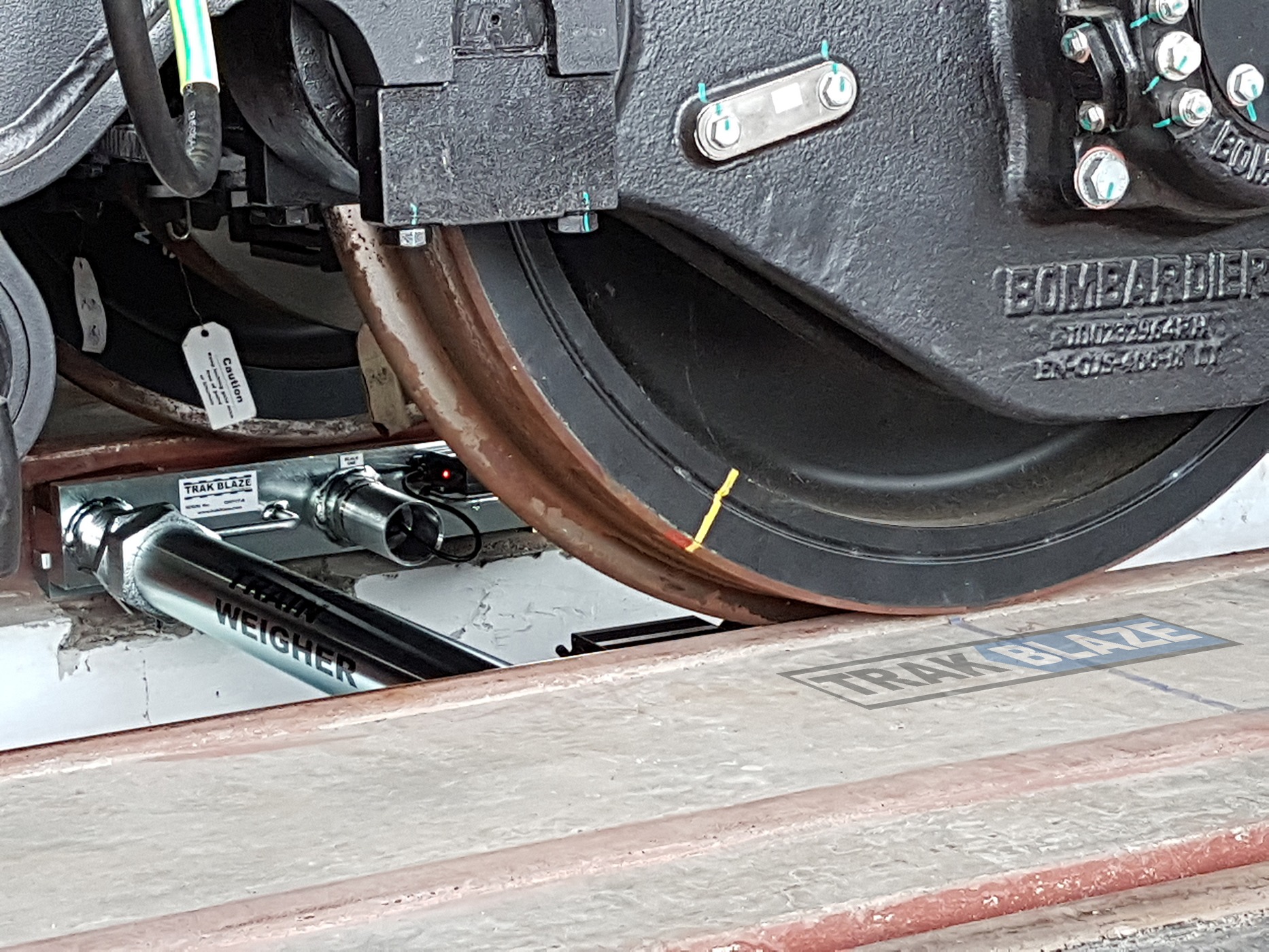

by Trakblaze

by Trakblaze

A portable train weighbridge is a versatile weighing system designed for weighing trains and their cargo in various locations. Unlike fixed or permanent weighbridges, portable train weighbridges offer the flexibility of being easily transported and set up at different sites as needed. They are typically designed modular and can be assembled and disassembled quickly, making them highly convenient for temporary or remote locations where a permanent weighbridge may not be feasible.

Unique Features and Components of Portable Train Weighbridges

Portable train weighbridges have specific features and components that enable mobility and functionality. They are typically constructed using lightweight materials without compromising durability and strength. The weighbridge components, such as load cells, junction boxes, and indicators, are designed to be easily assembled and disassembled. Portable train weighbridges also come with ramps and levelling systems to ensure proper alignment and stability during the weighing process.

Benefits of Portable Train Weighbridges

The use of portable train weighbridges offers several advantages in various scenarios. One significant benefit is their ease of relocation. These weighbridges can be quick to set up, dismantled and transported to different locations, allowing efficient weighing operations at multiple sites. This makes them ideal for temporary setups, construction sites, mining operations, and other remote locations where a fixed weighbridge may need to be more practical.

Another advantage of portable train weighbridges is their suitability for remote locations. They can be easily transported to areas with limited infrastructure or access to permanent weighbridges, providing a viable weighing solution in such challenging environments. Portable train weighbridges are often equipped with advanced technology and software, allowing accurate and efficient data collection and management.

Examples of Situations where Portable Train Weighbridges are Beneficial

Portable train weighbridges find applications in various industries and scenarios. Construction projects enable accurate weighing of construction materials and equipment brought to temporary job sites. In mining operations, where moving heavy machinery and equipment is common, portable train weighbridges ensure accurate weight measurement for effective load management. Similarly, portable weighbridges offer a reliable and convenient solution for monitoring train weight and cargo in remote or temporary railway operations.

Furthermore, portable train weighbridges are valuable in emergencies such as disaster relief efforts, where rapid deployment and accurate weighing of relief supplies and equipment are crucial. They also find applications in military operations, where the ability to establish weighing capabilities in different locations quickly is essential for logistical planning and resource management.

Static Train Weighbridges

A static train weighbridge is a fixed weighing system specifically designed for accurately measuring the weight of trains and their cargo. Unlike portable weighbridges, static train weighbridges are permanently installed at a designated location and provide a stable and reliable weighing solution.

Unique Features and Components of Static Train Weighbridges

Static train weighbridges are constructed using heavy-duty materials to ensure durability and withstand the heavy loads and constant use associated with train weighing operations. They consist of several key components, including load cells, concrete or steel decks, weighbridge instrumentation, and software for data management. These components work together to accurately measure the weight of trains as they pass over the weighbridge.

Benefits of Static Train Weighbridges

Static train weighbridges offer several advantages, making them a preferred choice in various scenarios. One significant benefit is their high durability and robust construction. Designed to handle heavy loads and endure continuous use, static weighbridges provide a long-lasting weighing solution that requires minimal maintenance.

Another advantage of static train weighbridges is their suitability for high-volume weighing operations. They are capable of weighing trains efficiently and accurately, making them ideal for railway terminals, distribution centres, and other locations where a large number of trains pass through regularly. Static weighbridges can handle high traffic volumes and provide precise weight measurements for effective load management and compliance with weight regulations.

Examples of Situations where Static Train Weighbridges are Beneficial

Static train weighbridges are indispensable equipment for various industries. They are needed in railway logistics to ensure weight restrictions and regulations compliance. They are commonly used in rail yards and terminals to accurately weigh trains before departure, helping to prevent overloading, derailments, and ensure safe transportation.

Static train weighbridges are also valuable in mining and bulk material handling, where accurate weight measurement is crucial for load planning and resource management. They provide precise weight data that helps optimise operations, control costs, and maintain safety standards.

Furthermore, static train weighbridges are beneficial in quality control processes. They enable accurate weighing of goods and materials during manufacturing and production, ensuring adherence to strict weight specifications and enhancing product quality.

Key Differences between Portable and Static Train Weighbridges

Each type has its characteristics and advantages, making them suitable for different scenarios and needs. Let’s explore the key differences between portable and static train weighbridges.

Installation Requirements and Mobility

One of the primary differences between portable and static train weighbridges is their installation requirements. Portable weighbridges are designed to be easily transported and assembled at different locations. They are typically modular in design, allowing for quick setup and relocation as needed. On the other hand, static weighbridges are permanently installed and require a more extensive installation process involving foundation construction and calibration.

Cost Considerations

Regarding cost, portable weighbridges are generally more affordable than static ones. Their modular design and ease of transportation contribute to lower installation and maintenance costs. On the other hand, static weighbridges involve a more substantial upfront investment due to their permanent installation and construction requirements.

Durability and Capacity

Static weighbridges are known for their robust construction and high durability. They are designed to handle heavy loads and endure continuous use, making them suitable for high-volume operations. While still durable, portable weighbridges may have lower weight capacities and must be ideal for heavy-duty or high-traffic weighing scenarios.

Accuracy and Precision

Both portable and static weighbridges are capable of providing accurate weight measurements. However, static weighbridges generally offer higher accuracy and precision due to their more stable and permanent installation. Portable weighbridges may be slightly more prone to fluctuations and variations, particularly if not set up on a level surface.

Suitability for Different Scenarios or Needs

The choice between portable and static weighbridges depends on specific requirements and scenarios. Portable weighbridges are ideal for situations where mobility and flexibility are crucial. They are commonly used for temporary weighing needs, remote locations, and construction sites. Portable weighbridges also offer a cost-effective solution for businesses with limited budgets.

Static weighbridges, on the other hand, are recommended for permanent weighing installations, high-volume operations, and scenarios that require high accuracy and durability. They are commonly found in railway terminals, distribution centres, and mining and bulk material handling industries.

Ultimately, selecting the most suitable weighbridge type depends on factors such as the intended use, budget, frequency of relocation, required weight capacity, and accuracy requirements.

Things to Consider When Choosing Between Portable and Static Train Weighbridges

Choosing the right type of weighbridge for your train weighing needs is essential to ensure accurate measurements and efficient operations. Several key factors should be considered when deciding between a portable and static train weighbridge. Let’s explore the important considerations that can help you make an informed decision.

Volume of Operations

Consider the volume of train weighing operations you anticipate. A static weighbridge may be more suitable if you have high-volume operations with frequent train weighings. Static weighbridges are designed for heavy-duty and continuous use, making them ideal for busy terminals or industries with substantial weighing requirements.

Site Conditions

Evaluate the site conditions where the weighbridge will be installed. If you require flexibility and the ability to relocate the weighbridge to different locations, a portable option might be better. Portable weighbridges are easily transportable and can be set up quickly at various sites. However, a static weighbridge can provide a reliable and long-term weighing solution if you have a permanent site with sufficient space and stable ground conditions.

Budget Considerations

Take into account your budget constraints when choosing a weighbridge. Portable weighbridges are generally more cost-effective in terms of initial investment and installation. They offer a modular design allowing easy assembly and transportation, reducing installation and maintenance costs. In contrast, static weighbridges require a more substantial upfront investment due to their permanent construction and foundation requirements.

Future Plans and Scalability

Consider your plans and potential expansion needs. A portable weighbridge offers greater flexibility and scalability if you anticipate an increase in weighing operations or changes in site locations. It can be easily moved and reconfigured to accommodate changing requirements. On the other hand, if you have a long-term site with no foreseeable changes, a static weighbridge provides a reliable and permanent weighing solution.

Accuracy Requirements

Assess the level of accuracy needed for your operations. Both portable and static weighbridges can deliver accurate weight measurements, but they generally offer higher precision due to their stable and fixed installation. If your operations require utmost accuracy, such as in industries with strict regulatory compliance or where precise weight measurements are critical, a static weighbridge may be preferable.

Maintenance and Calibration

Consider the maintenance and calibration requirements of the weighbridge. Portable weighbridges typically have lower maintenance needs, while static weighbridges may require periodic maintenance and calibration due to their permanent installation. Factor in the availability of resources and personnel for regular upkeep when deciding.

Choosing the right type of train weighbridge, whether portable or static, is crucial for accurate weight measurements and efficient operations. We have explored the key differences between these two types and discussed their unique features, benefits, and applications. Factors such as operations volume, site conditions, budget, future plans, accuracy requirements, and maintenance considerations should be carefully considered.

By selecting the appropriate weighbridge based on individual needs and circumstances, businesses can ensure optimal performance, cost-effectiveness, and compliance with weight regulations.

For more information or assistance in choosing the right train weighbridge, we encourage you to contact Trakblaze, a trusted provider of innovative weighing solutions in Australia.