Insights

Home | Insights

In most industrial environments, vehicle weighing occurs daily, across various shifts and often under time pressure. Weighbridges and scales are integrated into regular workflows and are rarely treated as separate technical tasks. Today’s operations need speed, reliability and adaptability.

Modern retail supply chains operate rapidly and at scale, moving high volumes of goods every day. Goods are shipped, handled, consolidated and redistributed across many locations. In this context, small data errors can quickly escalate, turning isolated mistakes into significant issues throughout the network.

Selecting the right weighing solution is not just a technical decision. For many operations, accurate weight data supports compliance, safety, billing and daily efficiency. When a weighing system is poorly matched to its application, operational delays and inefficiencies occur.

Vehicle weighing systems are essential for industries that require tracking vehicle weight in their operations. Accurate weighing helps manage load limits to support safe vehicle operations, monitor freight and ensure regulatory compliance.

Industrial weighing systems are essential in transport, mining and logistics operations. However, they are often evaluated as equipment purchases instead of long-term investments for operational efficiency. Once deployed, these systems impact weighing accuracy, compliance and decision-making for years to come.

Many heavy haulage vehicles operate across public and industrial transport networks every day. And when their loads push infrastructure beyond safe limits, the impact can be serious. Overloaded trucks, freight wagons, and aircraft accelerate structural wear on their routes, weaken load-bearing components, and compromise infrastructure safety and reliability.

Mining operations move massive volumes of material every day, and accurate weight measurement is crucial. To maintain smooth production, sites rely on accurate weighing data that shows exactly how much material is being loaded or transferred at any time.

One of the most essential but overlooked aspects of mining productivity is accurate load management. Each haul cycle depends on accurate load weight to ensure safety, compliance, fuel efficiency, and extended equipment lifespan.

Mining operations take place in one of the most challenging environments on the planet. Heavy machinery, extreme conditions, and continuous operations push equipment to its limits. Every load moved and measurement taken instantly impacts safety and productivity, making measurement reliability critical for success.

Accurate vehicle weighing can make or break a logistics operation. It ensures regulatory compliance, protects roads and infrastructure, and safeguards fleets from fines and penalties. However, the need for accurate truck weight goes beyond the rules and regulations.

Modern retail logistics operates on a significantly large scale. These distribution and loading-bay operations involve coordinating hundreds of truckloads, thousands of SKUs, and complex inventory systems, all while meeting strict timelines and compliance requirements.

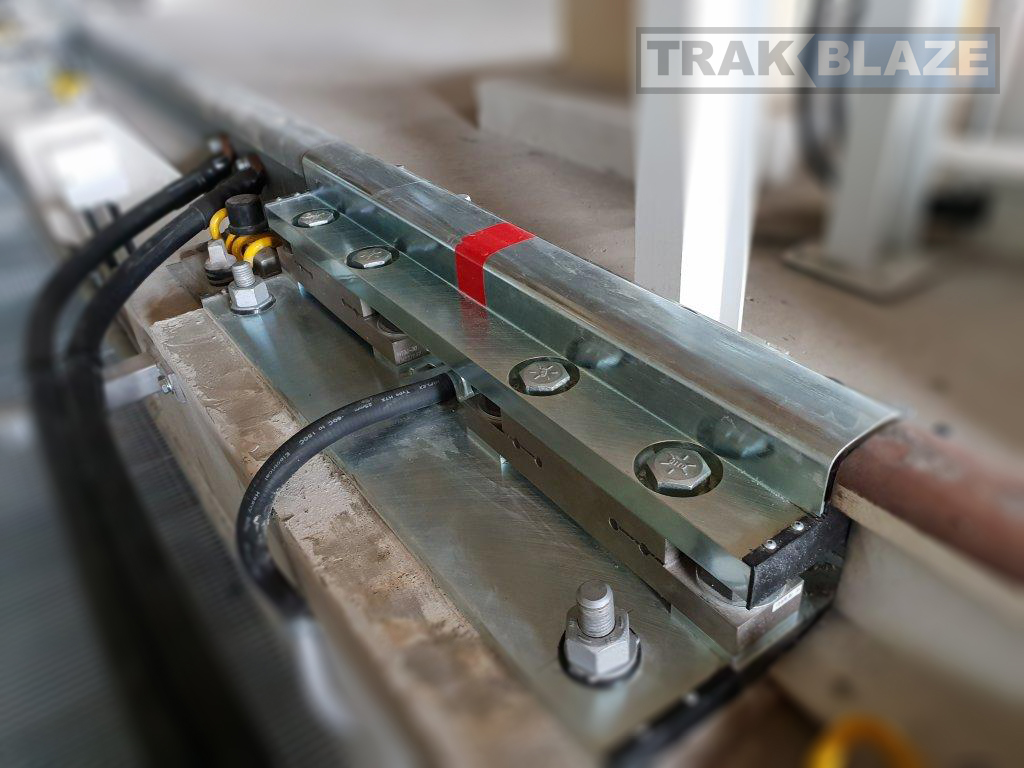

If you have experience in rail or industrial infrastructure projects, you may have noticed that the installation process can differ from one site to another. Some projects can be completed quickly with minimal disruption, while others may face delays.

Trakblaze Pty Ltd from Victoria, Australia continues to globally expand on its products and agent network, proudly announcing the appointment of KloverTel Private Limited from New Delhi, India as a new agent. KloverTel Private Limited will now facilitate Indian rail network enquiries for the industry proven Trakblaze Infinity series of low, medium and high speed …

The post Press Release: TRAKBLAZE appoints KLOVERTEL Private Limited (India) appeared first on Trakblaze.

Weighing and balancing are crucial in modern rail workshops. When rail vehicles are manufactured, repaired and maintained, they should return to service with correct weight distribution across wheels and axles to withstand heavy loads without compromising performance.

Rail operations rely on accurate weighing to support safety, operational efficiency and compliance. Depending on how your rail operations are structured, weighing may be required at various points, including depots, workshops, sidings, mining sites and temporary track sections.

Rail operators in mining, agriculture, construction, and manufacturing face increasing pressure to keep rail movement safe, efficient, and cost-effective. But if wagons run overweight or carry uneven loads, it increases strain on rails, sleepers, wheels, and brakes, and raises the risk of derailments.

Industries such as mining, rail, construction, and logistics rely on accurate data to ensure operations run safely and efficiently. Because these sectors handle continuous movement of heavy bulk materials, reliable weight data is essential for planning, monitoring, and cost efficiency.

Accurate rail weighing is an important consideration for ensuring safe and efficient rail operations. Mining loadouts, freight movements, and manufacturing facilities all require optimal load balancing and distribution to achieve performance, compliance, and asset longevity.

Rail is one of the most efficient ways to move large volumes of freight. To move cargo safely and profitably, operators need accurate weight data at every stage of the journey. That’s where rail weighing systems come in. From bulk minerals to agricultural products, every industry needs dependable load monitoring to manage costs and keep operations running smoothly.

Accurate vehicle weighing is vital for compliance, cost control, and efficiency in construction projects. Without a reliable weighing system in place, companies risk overloaded trucks, safety hazards, higher fuel costs, and regulatory fines, all of which can disrupt operations and drive up expenses.

Installing a weighbridge is more than just setting up a platform on-site. How the weighbridge is installed can affect its accuracy, compliance, and safety during daily operations. Partnering with a trusted weighing system supplier ensures the setup is correct, so every load is recorded accurately. It also helps with efficient site management and smooth traffic flow.

In many industries, accurate vehicle weight measurement is a requirement for safety, compliance, and efficiency. Overloaded or improperly balanced vehicles can lead to fines, increased wear on equipment, and increased risk of accidents. Due to this, investing in the right weighing systems is crucial for businesses that rely on heavy-duty transportation.

Installing a truck weighing system is only the beginning of its operational lifecycle. Regular servicing is essential to keeping it accurate, compliant, and performing at its best. This is especially important when your operations rely on precise weight data.

The Federal Government recently announced that the long-mooted $10 billion inland rail link between Melbourne and Brisbane will be one of 15 major infrastructure projects, worth a total of $72 billion, slated for fast-tracked approval as part of a “nation-building” infrastructure blitz aimed at boosting economic activity and job creation in the wake of the …

The post Australia’s Inland Rail Project – Implications For The Transport Sector appeared first on Trakblaze.

Another TRAKMATE weighing system has recently been installed, this time in Australia at the new Intercity Fleet Maintenance Facility, located at Kangy Angy, NSW, on the North Coast line. This facility will service and maintain a new fleet of 55 Intercity trains being supplied by South Korean company Hyundai Rotem to Transport of New South …

The post TRAKMATE at Kangy Angy – When Accuracy Matters! appeared first on Trakblaze.

With over seven million commuters each day, Singapore’s Land Transport Authority’s (LTA) network and infrastructure continues to grow and improve to better connect people and places. For those who have experienced Singapore’s network, you appreciate the excellence in customer service, network efficiency and one of the highest safety standards in the world. With LTA’s uncompromising …

The post Trakmate Out Weighs & Balances In Singapore… appeared first on Trakblaze.

IMARC 2019 Trakblaze – Stand K21 The international mining stage is front and centre once again with the 6th Annual International Mining Resources Conference commencing October 29 – 31 at the Melbourne Convention & Exhibition Centre and Trakblaze will again be a exhibiting at this exciting conference – Stand K21. More than ever before, …

The post IMARC 2019 appeared first on Trakblaze.

Having recently passed stringent South African SANS689 (OIML R106 equivalent) for Class 1 individual wagon weight up to 40kph, the INFINITY Rail Weighbridge will feature alongside the MTW (Mobile Train Weigher) and TRAKMATE (Rail workshop Weighing & Balancing) systems at the Railway Interchange Expo on September 22-25, 2019 at the Minneapolis Convention Center, Minneapolis, Minnesota, …

The post Trakblaze in the USA – Railway Interchange 2019 appeared first on Trakblaze.

Trakblaze Pty Ltd (India) and IPA India – thank the Confederation of Indian Industry for arranging yet another successful International Mining & Machinery Exhibition. We would also like to thank and acknowledge the Ministry of Mines Government of India, Coal India Limited, the Government of Jjarkhand and Australia Unlimited for their on going support for …

The post IMME 2018 – High Interest – Force Mining & Infinity Scales….. appeared first on Trakblaze.

The International Mining and Resources Conference typically known as IMARC is Australia’s largest mining conference that brings together Global Mining Leaders from around the World to connect with Technology, Finance and the Future. Trakblaze is proud to again support this conference and this year exhibit it’s latest volumetric technology for the Global Mining and Rail …

The post Trakblaze on show at IMARC 2018 – Stand D79 appeared first on Trakblaze.

Trakblaze proudly announces that we have now partnered with @CROSS Zlin, in delivering to Australasia – OptiWIM®; a Fibre-Optic Weigh In Motion (WIM) system which rewrites WIM innovation using patented unique Fibre-Optic Technology. Imagine a WIM system that can; • Measure at Class A3 with +- 3% accuracy • Provide the highest precision in free-flow traffic • Measure vehicles during …

The post Trakblaze partners with CROSS Zlin – OptiWIM. appeared first on Trakblaze.

On the back of progressive interest in the United States, TRAKMATE is fast becoming the talk of Short Rail Operators and will feature at this years SRLRRA (American Short Line and Regional Railroad Association) Expo at Gaylord Opryland Resort, Nashville – Booth # 111 – April 7 to 10, 2018. American Agent – Southwestern Scale Co. Inc. …

The post TRAKMATE features strongly at ASLRRA appeared first on Trakblaze.

Another respected corporate rail maintenance provider UGL Unipart in Auburn, New South Wales, Australia recently acquired Trakblaze’s Trakmate weighing and balancing system. UGL Unipart Rail Services Pty Ltd in Auburn, NSW was founded in December 2011 as a joint venture between UGL (Australia) and Unipart Rail (UK). The Joint Venture was formed following the successful bid …

The post Sydney Trains weighed & balanced by TRAKMATE appeared first on Trakblaze.

Discover How Trakblaze Benefits You

Have a question or need more information?

Fill out the form, and our team will get back to you shortly.

Mail Us

Become An Agent

Mail Us

Become An Agent