At a glance

- Accurate volumetric load measurement prevents revenue loss due to underreporting.

- Inaccurate measurements lead to increased operational costs and legal consequences.

- Despite initial investment, implementing accurate measurement technologies brings long-term economic benefits.

The mining industry is all about shifting the maximum amount of materials from one place to another efficiently. It is essential to get an accurate measurement of each load to increase revenue. When it comes to accurate measurement, there is a vast difference in traditional and modern approaches.

Weighing a load and converting it to volume, counting loader buckets, or counting loads are all traditional methods of determining haulage volume, which involves lots of guesswork, mainly resulting in an inaccurate measurement and financial loss.

If you still rely on a traditional method and it’s unavoidable – as the weight can vary according to moisture content and there is a high chance of human error.

There are so many small variations that could possibly change the weight or volume of the materials. However, these cannot be detected without the right methods.

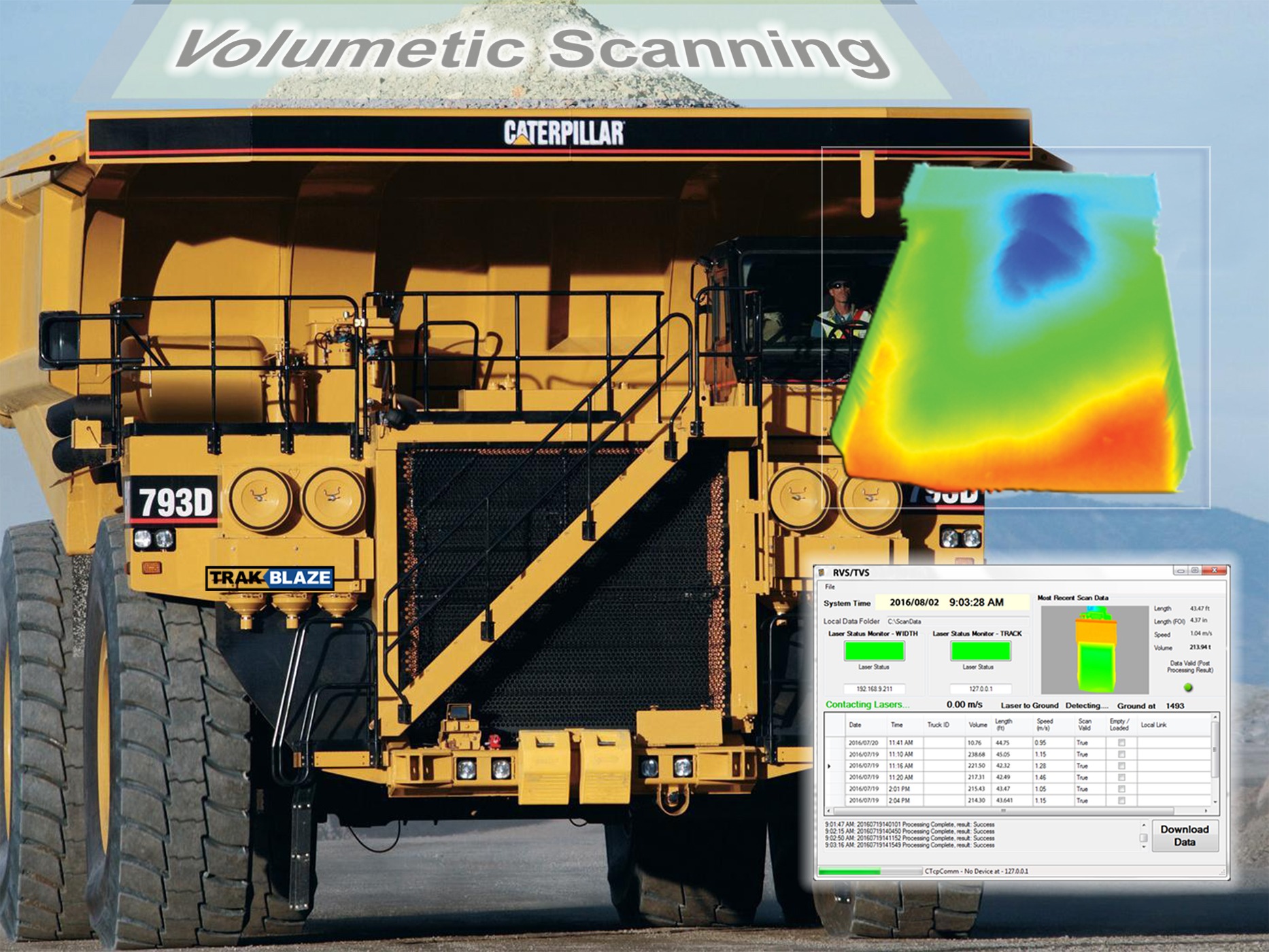

However, thanks to new technology – volumetric scanning has become the new definition of accurate measurements in Mining and rail sectors. With a combination of several new design elements, software updates and scanning specifications, we can now use a revolutionary measurement system – Volumetric Scanning.

The system works by comparing an empty tray against a loaded tray to compute the load volume. The truck needs to pass below the scan head, and the laser scanners start measuring the load volume, finally providing an accurate and detailed data analysis.

Measuring weight accurately is the most crucial factors for the mining industry; it has a significant impact on various areas like:

- Inventory tracking

- Cost control

- Operational efficiency

- Quality assurance and more

It also ensures that the loaded weight is legal according to states law, along with details of incoming and outgoing materials and a reduction in wastage.

Volumetric scanning is becoming more common in the Mining sector, and it has been a great help to understand the volume of the materials from the ground, irrespective of its weight. This new technology also ensures the loads are evenly distributed in a tray which helps to avoid the risk of overloading.

There have been many cases where a load has not been measured correctly leading to truck or road damage, a fine for overloading and loss of materials —not just overloading, but sometimes even under loading becomes a loss, by increasing the transportation cost. Now with the help of a volumetric scanner, you can 100% be sure your truck is loaded precisely – neither overloading nor under loading. Even in extreme environmental conditions, the accuracy and reliability of the scanner remain unaffected.

You won’t need to hire additional staff just for weighing the loads, which is an additional cost benefit that volumetric scanners offer. A single operator can run this automated weighing system smoothly without any hassle.

Economic Implications of Inaccurate Volumetric Load Measurement

Loss of revenue due to underreporting of mined material

The mining industry can suffer from big financial discrepancies when volumetric load measurements are inaccurate. The underreporting of mined material due to inaccurate measurements can directly affect businesses’ revenue. In addition to skewing data that are critical for forecasting and planning, this underreporting impacts the company’s overall financial situation.

Increased operational costs associated with overestimation or underestimation

There are multiple ways in which wrong measurement can increase operational costs. An overestimation may lead to overloaded vehicles that consume more fuel and wear out more quickly, resulting in higher maintenance costs. Underestimation, on the other hand, results in underutilisation of capacity, increasing fuel and labour costs unnecessarily, thus leading to higher costs.

Legal and regulatory consequences of inaccurate measurements

Regulatory and legal repercussions can also arise from inaccurate volumetric load measurements. It is possible for companies to incur fines and penalties if their reported volumes do not meet regulatory standards or contractual obligations. Additionally, persistent inaccuracies can harm a company’s reputation and cause it to lose contracts and lose trust with partners and regulators.

Cost-Benefit Analysis of Implementing Accurate Volumetric Load Measurement

Initial investment required for adopting accurate measurement technologies

An initial capital investment is required for advanced technologies such as a Mobile Volumetric Scanner or a Mining Haul Truck Volumetric Scanner. This involves the costs of purchasing new equipment, training personnel to operate these systems, and integrating these technologies into existing operations. In spite of this, this initial investment is aimed at improving long-term operational effectiveness.

Potential cost savings and revenue gains from improved accuracy

It is possible to save substantial amounts of money and increase revenue by adopting precise measurement technologies like RVS, MVS and TVS. A precise load measurement minimises the risk of underreporting and overestimating, maximising revenue generation from transportation. Furthermore, reducing operational inefficiencies like fuel consumption and vehicle maintenance can save significant amounts of money.

Long-term economic benefits versus short-term implementation costs

It may be costly to implement accurate volumetric load measurement systems in the short term, but the long-term economic benefits far outweigh these costs. As a result of improved measurement accuracy, operational efficiency is improved, legal risks are reduced, and regulation compliance is improved. By improving profitability and generating a solid return on investment, these benefits justify the initial costs of modernising measurement systems.