Volumetric Scanning is rapidly emerging as a viable alternative or complementary method to traditional weighing in various industrial sectors, including rail, mining, and aviation. Leveraging laser precision and unparalleled reliability, Volumetric Scanning utilises an elevated scan head to conduct a comprehensive analysis of materials from the ground up. This approach ensures uniform load distribution, minimises maintenance costs, and effectively addresses concerns related to overloading.

Trakblaze, a pioneer in this technology, offers trademarked Volumetric Scanners tailored to specific industries. In this discussion, we will delve into the applications and advantages of Trakblaze’s Rail Volume Scanner and compare it with the functionality of the Mining Truck Volumetric scanner. By doing so, we aim to highlight the optimisation possibilities for each scanner variant.

Both the Rail Volume Scanner and Mining Truck Volumetric scanner boast a user-friendly interface, incorporating a myriad of design elements, scanning specifications, and software functionalities. These attributes are the result of meticulous engineering and software innovation, setting industry benchmarks and paving the way for more streamlined operations.

Rail

Application

The Trakblaze Rail Volume Scanner (RVS) is a cutting-edge weighing instrument designed specifically for the rail industry. Its application involves the accurate and rapid recording of volumetric measurements for each type of wagon on a designated track. Equipped with advanced ‘auto scan’ software, the RVS employs an aerial scan head, utilising high-speed 2D lasers for direct acquisition of key metrics.

Operators in the rail industry benefit significantly from the RVS’s customised algorithm embedded in its software. This algorithm enables precise recording of load volume scanner information and measurement parameters for each train. This capability not only enhances the efficiency of loading operations but also provides near real-time outputs. The ability to replicate these outputs across various projects contributes to the scalability and versatility of the system.

Benefits

Enhanced Efficiency: The RVS’s advanced software and custom algorithm streamline the volumetric measurement process, significantly improving the efficiency of loading operations in the rail industry. This leads to quicker turnaround times and optimised workflow.

Real-Time Monitoring:

The near real-time outputs provided by the RVS contribute to effective monitoring of loading activities. This instantaneous feedback allows operators to make timely adjustments, ensuring that the loading process adheres to set parameters and standards.

Easy Installation and User-Friendly Interface:

The RVS offers ease of implementation with its user-friendly interface and straightforward installation process. This feature minimises downtime and allows for quick integration into existing rail operations.

Industry-Standard Data Delivery:

The provision of an industry-standard data delivery mechanism ensures compatibility with existing rail systems and facilitates seamless communication of volumetric measurement data. This interoperability enhances the overall effectiveness of the rail industry’s data management processes.

Pre-Calibration for Accuracy:

The pre-calibration feature of the RVS reduces the need for trial measurements, ensuring accurate volumetric data from the outset. This not only saves time but also enhances the reliability of the measurements, contributing to improved decision-making in the rail industry.

Mining

Application

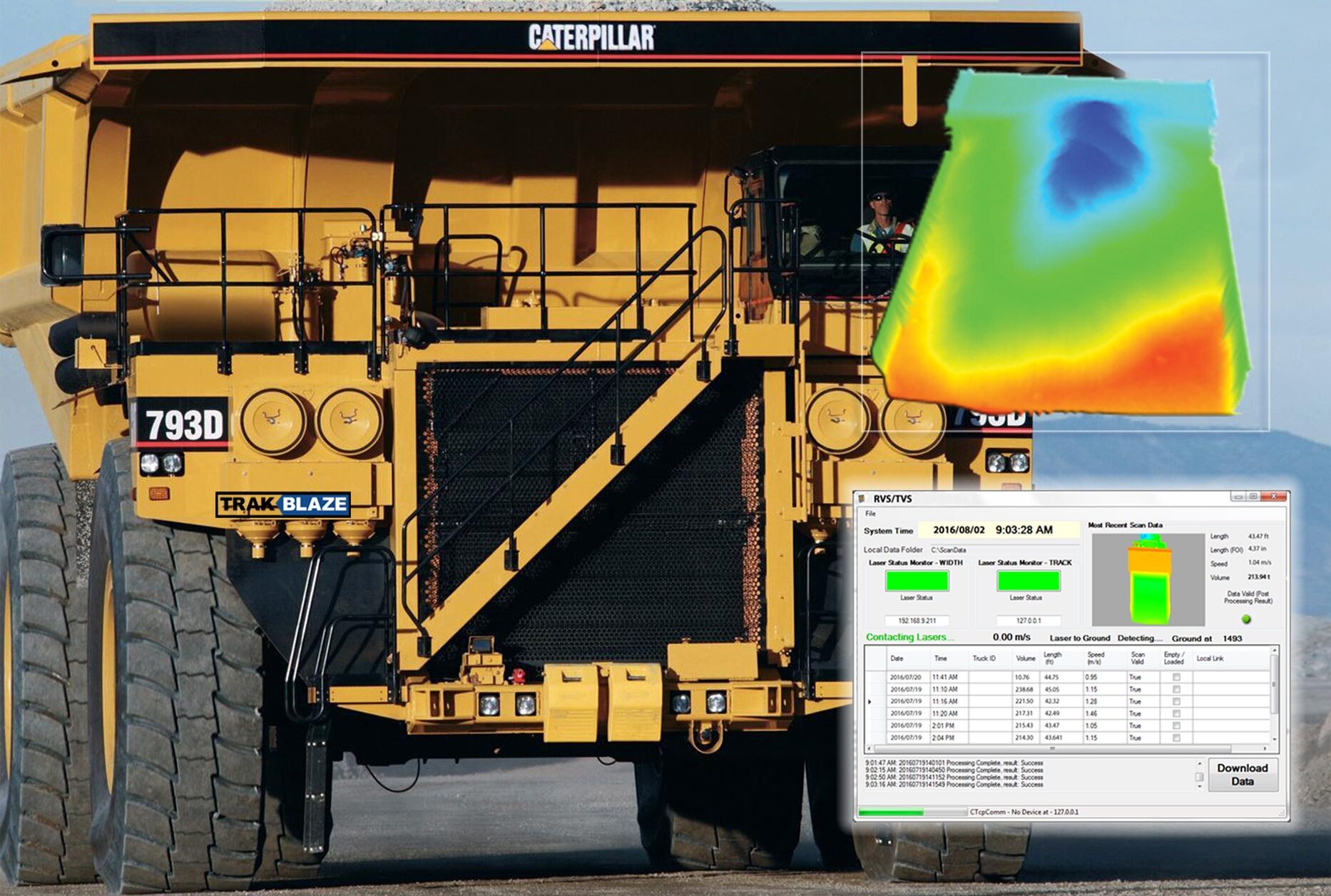

Trakblaze’s Mining Truck Volumetric Scanner is a revolutionary technology designed for the mining industry. Its primary application lies in accurately measuring bulk loose solids in dump trucks that pass beneath its scan head. This capability is crucial for precise reporting and optimising payloads in mining operations. Similar to the Rail Volume Scanner (RVS), the TVS performs thousands of distance measurements per second, providing real-time data and key metrics to operators and contributing to continuous operational improvement.

The application process of the TVS begins with the construction of a 3D model or an ’empty vehicle profile.’ During this phase, an empty truck is scanned and recorded into the system, serving as a reference point for subsequent measurements. The TVS then utilises this empty vehicle profile as a benchmark, comparing each new load against it during subsequent scans to compute the load volume accurately.

Benefits

Payload Optimisation:

The TVS plays a crucial role in optimising payloads by accurately measuring the volume of bulk loose solids in dump trucks. This information allows mining operators to maximise the efficiency of each haul, ensuring that trucks are loaded to their optimal capacity without exceeding safety limits.

Accurate Reporting:

The TVS provides precise and reliable data on the volume of materials in each dump truck. This accuracy enhances the quality of reporting, supporting decision-making processes, and facilitating compliance with regulatory requirements.

Real-Time Data Feedback:

With its ability to perform thousands of distance measurements per second, the TVS offers real-time data feedback to operators. This timely information enables quick decision-making and adjustments to improve the overall efficiency of mining operations.

Continuous Improvement:

The TVS contributes to continuous operational improvement by providing ongoing data and key metrics. Mining operators can use this information to identify areas for enhancement, implement changes, and fine-tune processes for increased productivity.

Efficient 3D Modelling

The construction of an ’empty vehicle profile’ through 3D modelling ensures accurate and consistent measurements. This approach minimises errors and establishes a reliable baseline for comparing subsequent loads, contributing to the overall precision of volumetric measurements in the mining industry.

Tailoring measurement systems to the unique needs of each project is paramount for ensuring operational effectiveness. While both the Rail Volume Scanner (RVS) and Mining Truck Volumetric Scanner (TVS) leverage similar cutting-edge technology to enhance accuracy and speed, a nuanced understanding of their distinct applications is crucial for informed decision-making during project planning.

Fortunately, Trakblaze, boasting over 90 years of expertise as an international leader in high-quality industrial weighing systems, offers an extensive range of trademarked products. These products not only signify Trakblaze’s commitment to advancing the industry but also exemplify their dedication to innovation. Through their proven solutions, Trakblaze has empowered numerous businesses to enhance their operational efficiency and achieve success in diverse operational landscapes.